|

Wastewater biotreatment. Secondary treatment

|

|

|

|

Wastewater biotreatment

To maintain the ecological balance in the receiving water, regulatory authorities have set standards for the maximum amount of the undesirable compounds present in the discharge water. In a typical wastewater treatment plant, the following steps are carried out to achieve the desired quality of the effl uent before it can be safely discharged into the receiving water.

Pretreatment/preliminary treatment

Pretreatment is primarily used to protect pumping equipment and promote the success of subsequent treatment steps. Pretreatment devices such as screen and/or grit removal systems are designed and implemented to remove the larger suspended or fl oating solids, or heavy matter that can damage pumps. Sometimes, froth fl otation is also used to remove excessive oils or grease in the wastes.

Primary treatment

Most of the settleable solids are removed from the wastewater by simple sedimentation, a purely physical process. In this process, the horizontal velocity of the water through the settle is maintained at a level that provides solids adequate time to settle and fl oatable material be removed from the surface. Therefore, primary treatment steps consist of settling tanks, clarifiers, or fl otation tanks, which send separated solids to digestion units and supernatant to subsequent, typically microbiological, treatment units.

Secondary treatment

Secondary treatment uses microbial communities, under varying growth conditions, to biochemically decompose organic compounds in the waste that have passed from primary treatment units. An array of reactors are employed for biological treatment, which include suspended biomass, biofilm, fixed-film reactors, and pond or lagoon systems.

- Secondary Clarification

Most biological treatment processes produce excess biomass through the conversion of waste carbon to new cells. As such, before the final treatment steps, such as disinfection or nutrient removal, solids must be separated from the secondary treatment effl uents. This is usually by settling, but membranes are also employed. The separated solids are either recycled back to the head of the process train or sent to digesters for solids reduction and processing, depending on the type of the digester system.

Tertiary/advanced treatment

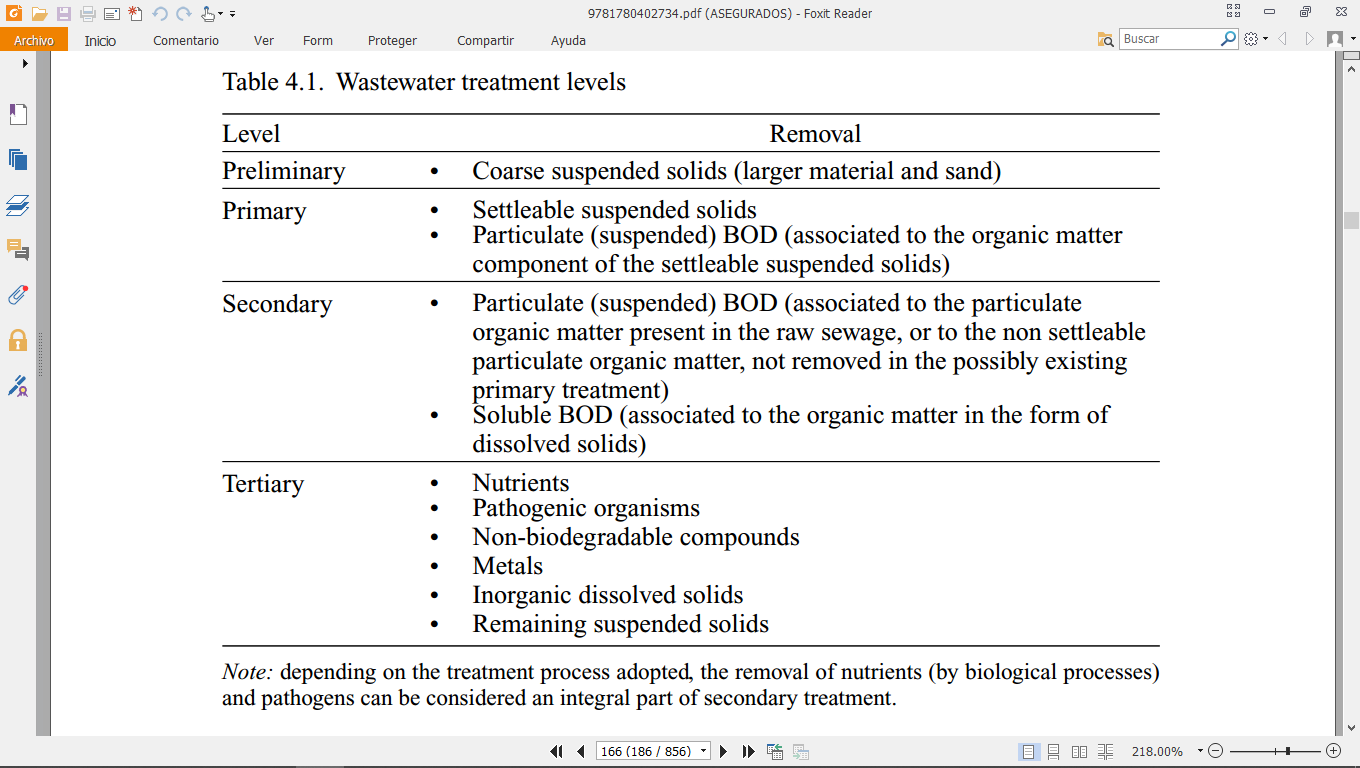

Advanced or tertiary treatment consists of processes that are designed to achieve higher effl uent quality than attainable by conventional secondary treatment methods. These include polishing steps such as activated carbon adsorption, ion exchange, reverse osmosis, electrodialysis, chemical oxidation, and nutrient removal. Although not technically a tertiary process, final effl uent disinfection is often performed after secondary or tertiary treatment using chlorination, ultraviolet methods, ozonation, and other methods designed specifically to kill residual organisms in the wastewater after all previous treatment steps. In Table 1 are summarized the four steps of a typical wastewater treatment plant.

|

|

|

Table 1. Wastewater treatment steps

Note: BOD, Biochemical Oxygen Demand

Only the secondary treatment as a process that uses microorganisms in the removal of contaminants will be considered.

Secondary treatment

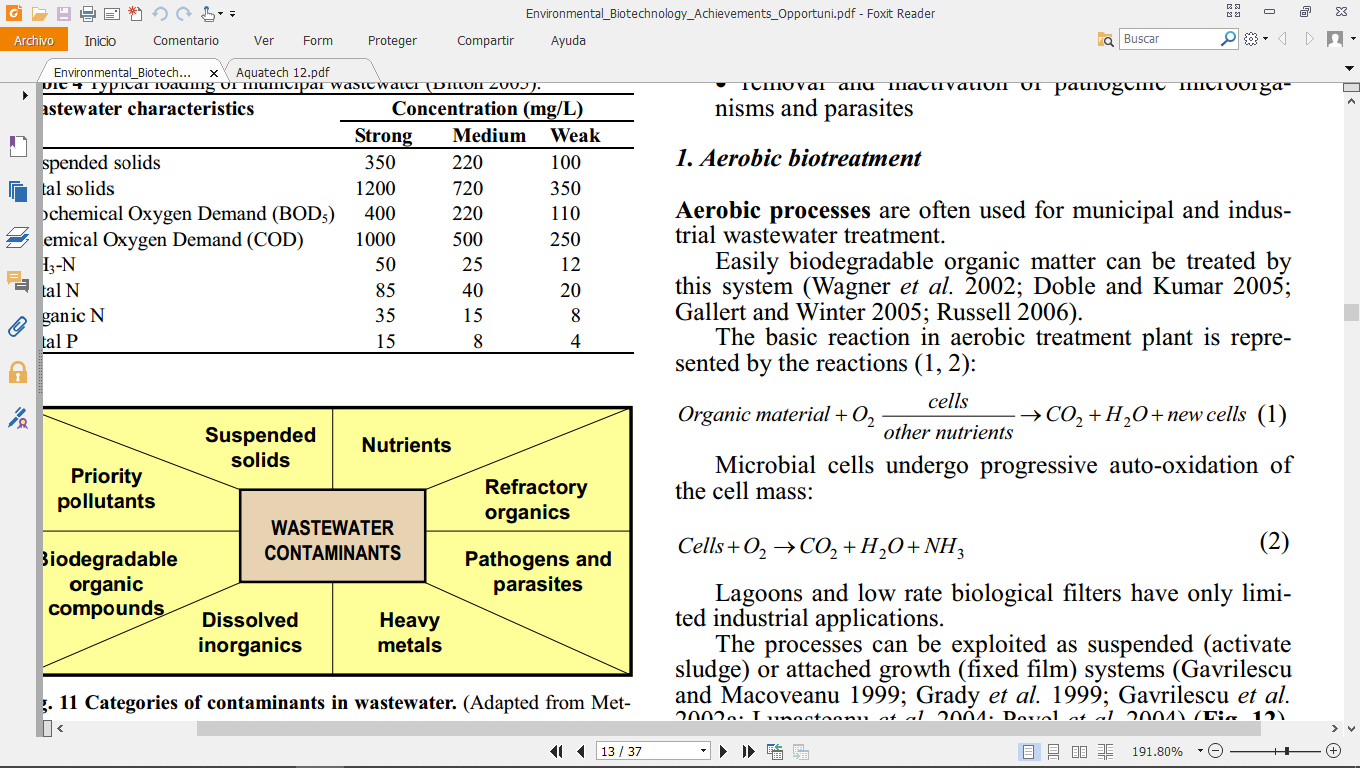

The use of microorganisms to remove contaminants from wastewater is largely dependent on wastewater source and characteristics.

Wastewater is typically categorized into one of the following groups:

- municipal wastewater (domestic wastewater mixed with effluents from commercial and industrial works, pre-treated or not pre-treated)

- commercial and industrial wastewater (pre-treated or not pre-treated)

- agricultural wastewater

The effluent components may be of chemical, physical or biological nature and they can induce an environmental impact, which includes changes in aquatic habitats and species structure as well as in biodiversity and water quality.

The quality parameters are very diverse, so that the biological wastewater treatment has to be adequate to pollution loading. Therefore, it is a difficult task to find the most appropriate microorganism consortia and treatment scheme for a certain type of wastewater, in order to remove the non-settleable colloidal solids and to degrade specific pollutants such as organic, nitrogen and phosphorus compounds, heavy metals and chlorinated compounds contained in wastewater.

Since many of these compounds are toxic to microorganisms, pretreatment may be required. Biological treatment requires that the effluents be rich in unstable organic matter, so that microbes break up these unstable organic pollutants into stable products like CO2, CO, NH3, CH4, H2S, etc.

To an increasing extent, wastewater treatment plants have changed from “end-of-pipe” units toward module systems, most of them fully integrated into the production process (production integrate environmental protection).

The main objectives of wastewater treatment processes can be summarized as:

- reduction of biodegradable organics content (BOD5)

- reduction/removal of recalcitrant organics

- removal of heavy/toxic metals

- removal/reduction of compounds containing P and N

- removal and inactivation of pathogenic microorganisms and parasites

The three major groups of biological processes: aerobic, anaerobic, combination of aerobic and anaerobic can be run in combination or in sequence to offer greater levels of treatment.

· Aerobic biotreatment

Aerobic processes are often used for municipal and industrial wastewater treatment. Easily biodegradable organic matter can be treated by this system.

The basic reaction in aerobic treatment plant is represented by the reactions (1, 2):

Microbial cells undergo progressive auto-oxidation of the cell mass:

Apart from a classification based on microbial metabolism and/or oxygen utilization, biological wastewater treatment processes also can be classified based on the growth conditions in the reactor. In this case, the two main categories are suspended growth and attached growth processes.

Suspended growth processes

In these processes, the microorganisms, which are responsible for the conversion of waste organic matter to simpler compounds and biomass, are maintained in suspension within the liquid phase. However, there are different types of aerobic and anaerobic suspended growth processes.

|

|

|

Aerobic processes include activated sludge, aerated lagoons, and sequencing batch reactors, whereas anaerobic processes include bag digesters, plug-fl ow digesters, stirred-tank reactors, and baffl ed reactors with organisms primarily in the liquid phase.

Attached growth process

In these processes, the microorganisms responsible for degrading the waste are attached to surfaces (e. g., stones, inert packing materials), or are self-immobilized on fl ocs or granules in the system. Attached growth processes can be aerobic or anaerobic. Aerobic attached growth processes include trickling filters, roughing filters, rotating biological contactors, and packed-bed reactors. Anaerobic system include upfl ow packed-bed reactors, down-fl ow packed-bed reactors, anaerobic rotating biological contactors, anaerobic fl uidized bed reactors, upfl ow anaerobic sludge blanket (UASB) reactors, and various hybrid anaerobic reactors (HAR). UASBs are widely used reactors for the anaerobic treatment of industrial and domestic wastewater.

Domestic wastewaters are usually treated by aerobic activated sludge process, since they are composed mainly of proteins (40-60%), carbohydrates (25-50%), fats and oils (10%), urea, a large number of trace refractory organics (pesticides, surfactants, phenols).

Activated sludge process (ASP)

Classic ASPs are aerobic suspended cell systems. As previously indicated, mineralization of waste organic compounds is accompanied by the formation of new microbial biomass and sometimes the removal of inorganic compounds, such as ammonia and phosphorus, depending on the particular process design. Activated sludge processes were first conceived in the early 1900s with the word “activated” referring to solids that catalyze the degradation of the waste. It was subsequently discovered that the “activation” part of the sludge was a complex mixture of microorganisms. The liquid in activated sludge systems is called the “mixed liquor”, which includes both wastewater and the resident organisms.

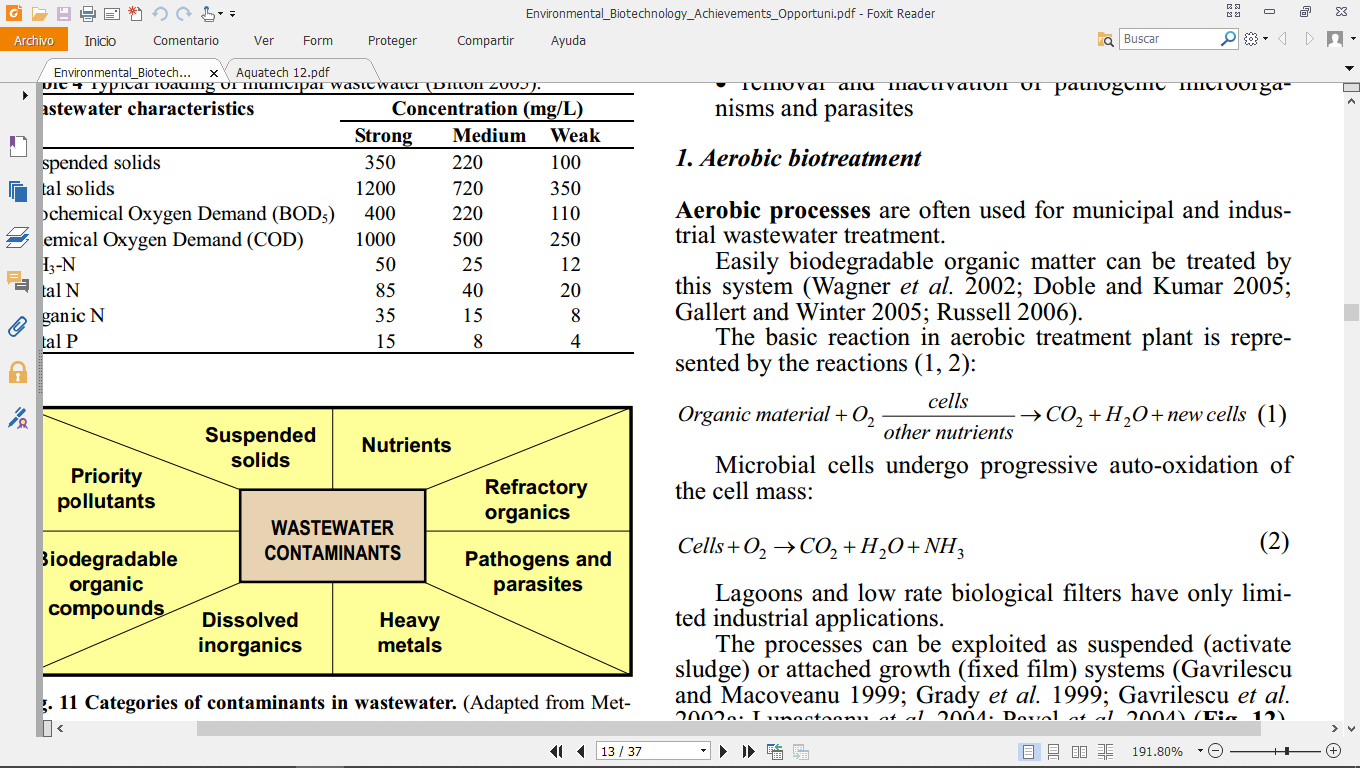

There are several types of ASPs. The most common designs use conventional, step aeration, and continuous-fl ow stirred-tank reactors. A conventional ASP consists of standard pretreatment steps, an aeration tank, and a secondary clarifier, an example of which is shown in Fig. 5. The aeration tank can be aerated by subsurface or surface aerators designed to supply adequate dissolved oxygen to the water for growing of the microorganisms.

Fig. 5. Activated sludge process.

The wastewater fl ows through the tank and resident microorganisms consume organic matter in the wastewater. The aeration tank effl uent fl ows to the clarifier where the microorganisms are removed. The clarifier supernatant is then transferred to disinfection or treatment units, and then ultimately discharged to the receiving water. Biosolids from the settler are recycled back to the head of the treatment system or sent to digesters for further processing.

Aeration tanks are usually designed uncovered, open to the atmosphere. Air is supplied to the microorganisms by two primary methods: mechanical aerators or diffusers. Mechanical aerators, such as surface aerators and brush aerators, aerate the surface of the water mechanically and promote diffusion of oxygen to water from the atmosphere. The concentration of dissolved oxygen in the liquid can be controlled by adjusting the speed of the rotors. Both mechanical aerators and diffusers are the largest energy consumers in aerobic biological wastewater treatment processes. Diffusers bubble air directly into the tank at depth and are usually preferred because of higher oxygen transfer efficiencies.

As is already known, aeration provides O2 to the microorganisms and serves to mix the liquor in the tank. Although complete mixing is desired, there are usually “dead zones” in the tank where anaerobic/anoxic conditions develop in poorly mixed areas. It is desirable to keep these zones to a minimum to minimize undesired odors and problems with sludge bulking, which can reduce settling efficiency in secondary clarifiers. Advanced types of activated sludge systems use pure oxygen instead of air and can operate at higher biomass concentration.

|

|

|

Clarifiers are used to separate the biomass and other solids coming out of the aeration tank by means of gravity settling. The fl ow rate of the liquid is maintained in such a way that the upfl ow velocity of the liquid is less than the settling velocity of the biosolids present in the liquid. As noted, some of the settled biosolids are returned back to the aeration tank to increase the solids’ contact time with the wastes and maintain the desired biomass levels in the aeration tank.

Important operating parameters of ASP.

Solid Retention time (SRT)

The most important design parameter in activated sludge systems is the mean cell residence time of cells in the reactor, also known as the sludge age or SRT. The SRT can be controlled by manipulating the rate at which excess sludge is wasted and is infl uenced by hydraulic fl ow conditions through the reactor. It is the ratio of the total solids in the system and the total solids leaving the system.

Sludge volume index (SVI)

The SVI is another key parameter and used to describe the settling characteristics of the sludge. The SVI is expressed as the volume occupied by 1 g of sludge (mL/g) after 30 min of settling time. Well-settled sludge normally yields a clear separation between the water and the sludge.

Dissolved oxygen Concentration

Microorganisms in an activated sludge system require adequate oxygen to oxidize organics in the waste. The basic oxidation reaction for organics degradation can be approximated as (stoichiometry not provided)

CHON + O2 + microorganisms = CO2 + H2O + NH3 + more microorganisms

Organics are consumed by microorganisms, and new microbial cells are synthesized with ratio of organisms produced relative to the organics consumed being the sludge yield. As noted, oxygen is supplied by mechanical aerators or diffusers in the aeration tank. Required oxygen levels in the system depend on the process, but the design goal is to minimize oxygen addition due to energy costs. The dissolved oxygen concentration can be controlled by either adjusting the speed of the air pump or throttling the air pipes. Air pumps are more widely used to aerate the wastewater because of their lower operational and maintenance costs.

Food-to-microorganism Ratio (F/M)

The F/M is a good indicator for designing and regulating the operation of the aeration tank. The F/M ratio is expressed as the amount of organic biodegradable material available for microorganisms present per day.

The targeted F/M ratio for any treatment system varies depending on the design of the system, and values can range widely.

Organic loading Rate

The amount of organic matter in wastewater is commonly measured by BOD5 (5-days biological oxygen demand), chemical oxygen demand (COD), or the total organic carbon content. If there are excess organics in the infl uent or inadequate organisms in the aeration tank, incomplete treatment will result.

Common microorganisms in activated sludge systems

Activated sludge is a complex mixture of broadly differing microorganisms. Major categories are as follows: bacteria, fungi, algae, protozoa (e. g., fl agellates, ciliates, and rotifers), and viruses. Viruses and pathogenic bacteria are often present in wastewater, which is the primary reason for having post-biological disinfection steps in treatment plants.

|

|

|

· Anaerobic treatment

Anaerobic treatment itself is very effective in removing biodegradable organic compounds, leaving mineralized organic compounds like NH4+, PO43-, S2- in the solution. Anaerobic treatment can be conducted in technically plain systems, and process can be applied at any scale and at almost any place.

Moreover, the amount of produced sludge is very small and very stabilized, even having a market value when the so-called granular anaerobic sludge is produced in the bioreactor. In addition, useful energy in the form of biogas is produced instead of high-grade energy consumed.

The anaerobic treatments are implemented to treat wastewaters rich in biodegradable organic matter (BOD > 500 mg L-1) and for further treatment of sedimentation sludges. Strong organic wastewaters containing large amounts of biodegradable materials are discharged mainly by agricultural and food processing industries. These wastewaters are difficult to be treated aerobically due to the troubles and expenses of fulfillment of the elevated oxygen demand to preserve the aerobic conditions. In contrast, anaerobic degradation occurs in the absence of oxygen. Although the anaerobic treatment is time-consuming, it has a multitude of advantages in treating strong organic wastewaters. These advantages include elevated levels of purification, aptitude to handle high organic loads, generating small amounts of sludges that are usually very stable, and production of methane (inert combustible gas) as end-product.

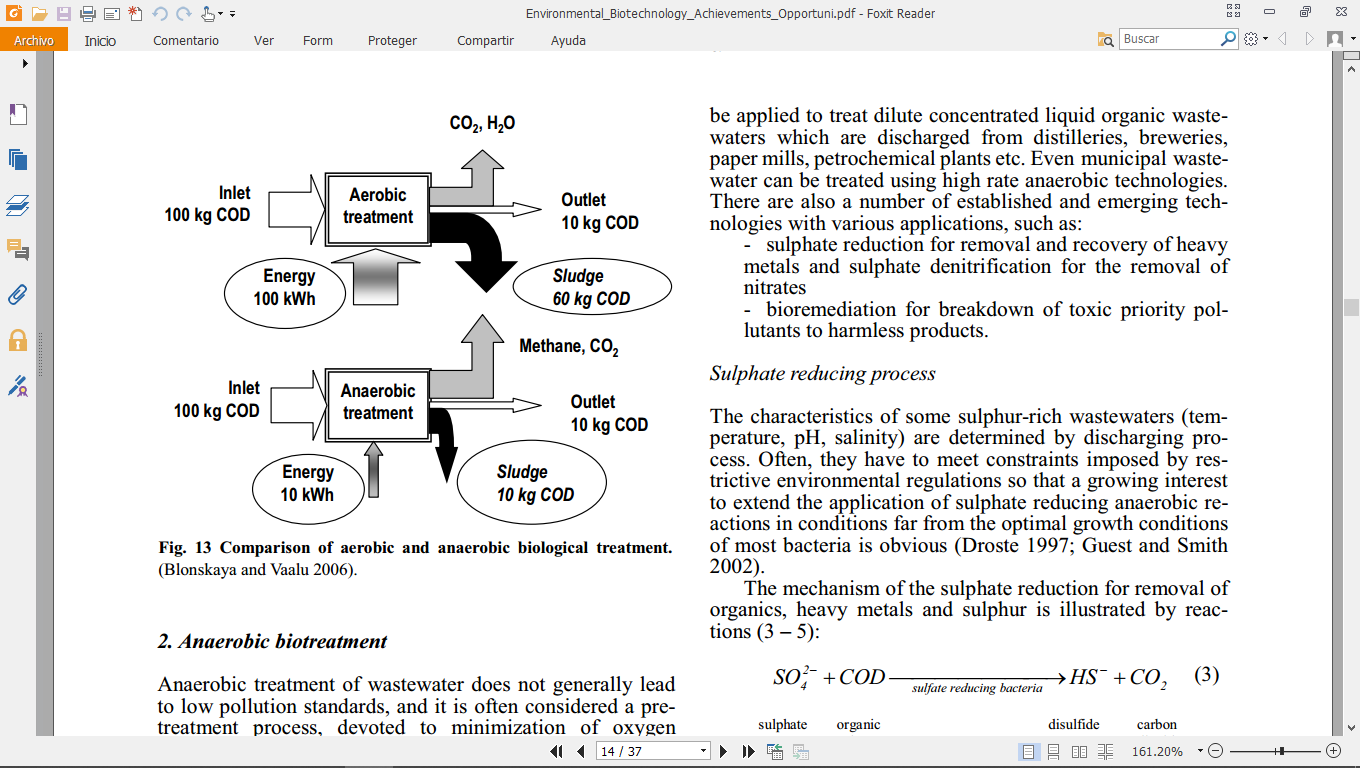

Anaerobic treatment of wastewater does not generally lead to low pollution standards, and it is often considered a pretreatment process, devoted to minimization of oxygen demand and excessive formation of sludge. Highly concentrated wastewaters should be treated anaerobically due to the possibility to recover energy as biogas and low quantity of sludge. Research and practices have demonstrated that high loads of wastewater treated by anaerobic technologies generates low quantities of biological excess sludge with a high treatment efficiency, low capital costs, no oxygen requirements, methane production, low nutrient requirements. Figure 6 shows the outcome of carbon and energy in both aerobic and anaerobic wastewater treatment assuming that the oxidation of 100 kg COD requires 100 kWh of aeration energy. In contrast to anaerobic treatment, aerobic treatment is generally characterized by high operational costs (energy), while a very large fraction of the waste is converted to another type of waste (sludge). Aerobic treatment in a conventional activated sludge process yields around 60% new sludge from COD converted, which requires further treatment (anaerobic digestion) before it is reused, disposed off or incinerated.

Figure 6. Comparison of aerobic and anaerobic biological treatment.

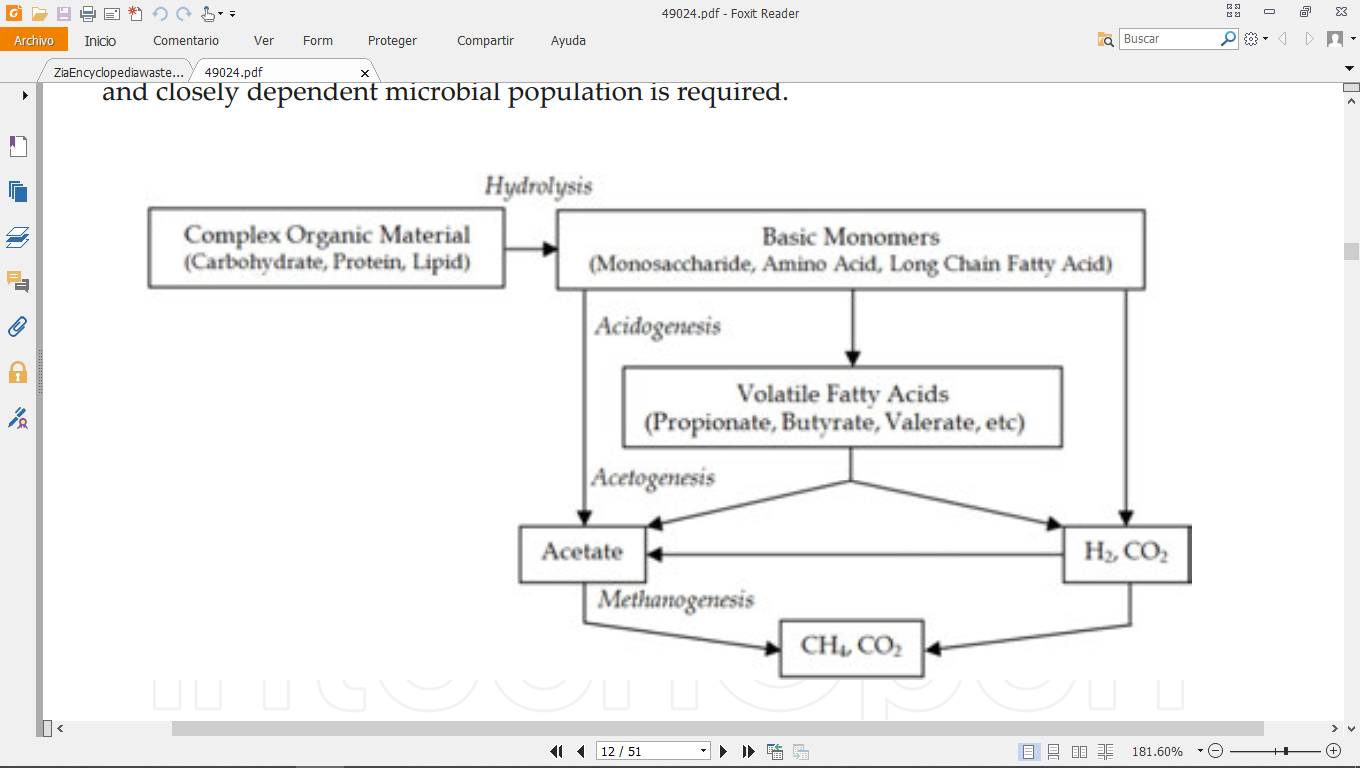

Under anaerobic conditions, organic matter is degraded through the sequential and syntrophic metabolic interactions of various trophic groups of prokaryotes, including fermenters, acetogens, methanogens, and sulfate-reducing bacteria (SRB). Metabolic interactions between these microbial groups lead to the transformation of complex organic compounds to simple compounds such as methane, carbon dioxide, hydrogen sulfide, and ammonia (Fig. 7). The digestion process is essentially accomplished in four major reaction stages involving different microorganisms in each stage.

Fig. 7. Stages of the anaerobic digestion process.

Stage 1: Hydrolysis. The organic waste material mainly consists of carbohydrates, proteins, and lipids. Complex and large substances are broken down into simpler compounds by the activity of the microbes and the extracellular enzymes released by these microbes. The hydrolysis or solubilization is mainly done by hydrolytic microbes such as Bacteroides, Bifidobacterium, Clostridium, and Lactobacillus. These organisms hydrolyze complex organic molecules (cellulose, lignin, proteins, and lipids) into soluble monomers such as amino acids, glucose, fatty acids, and glycerol. These hydrolysis products are used by the fermentative acidogenic bacteria in the next stage.

Stage 2: Acidogenesis. Fermentative acidogenic bacteria convert simple organic materials such as sugars, amino acids, and long-chain fatty acids into short-chain organic acids such as formic, acetic, propionic, butyric, valeric, isobutyric, isovaleric, lactic, and succinic acids; alcohols and ketones (ethanol, methanol, glycerol, and acetone); carbon dioxide; and hydrogen. Generally, acidogenic bacteria have high growth rates and are the most abundant bacteria in any anaerobic digester. The high activity of these organisms implies that acidogenesis is never the rate-limiting step in the anaerobic digestion process. The volatile acids produced in this stage are further processed by microorganisms characteristic for the acetogenesis stage.

|

|

|

Stage 3: Acetogenesis. In this stage, acetogenic bacteria, also known as obligate hydrogen-producing acetogens, convert organic acids and alcohols into acetate, hydrogen, and carbon dioxide, which are subsequently used by methanogens and SRB. There is a strong symbiotic relationship between acetogenic bacteria and methanogens. Methanogens and SRB use hydrogen, which helps achieve the low hydrogen pressure conditions required for acetogenic conversions.

Stage 4: Methanogenesis. It is the final stage of anaerobic digestion where methanogenic archaea convert the acetate, methanol, methylamines, formate, and hydrogen produced in the earlier stages into methane. The growth rate of methanogens is very low, and therefore, in most cases, this step is considered as the rate-limiting step of the anaerobic process, although there are also examples where hydrolysis is rate limiting.

Upflow anaerobic sludge bed (UASB) reactors

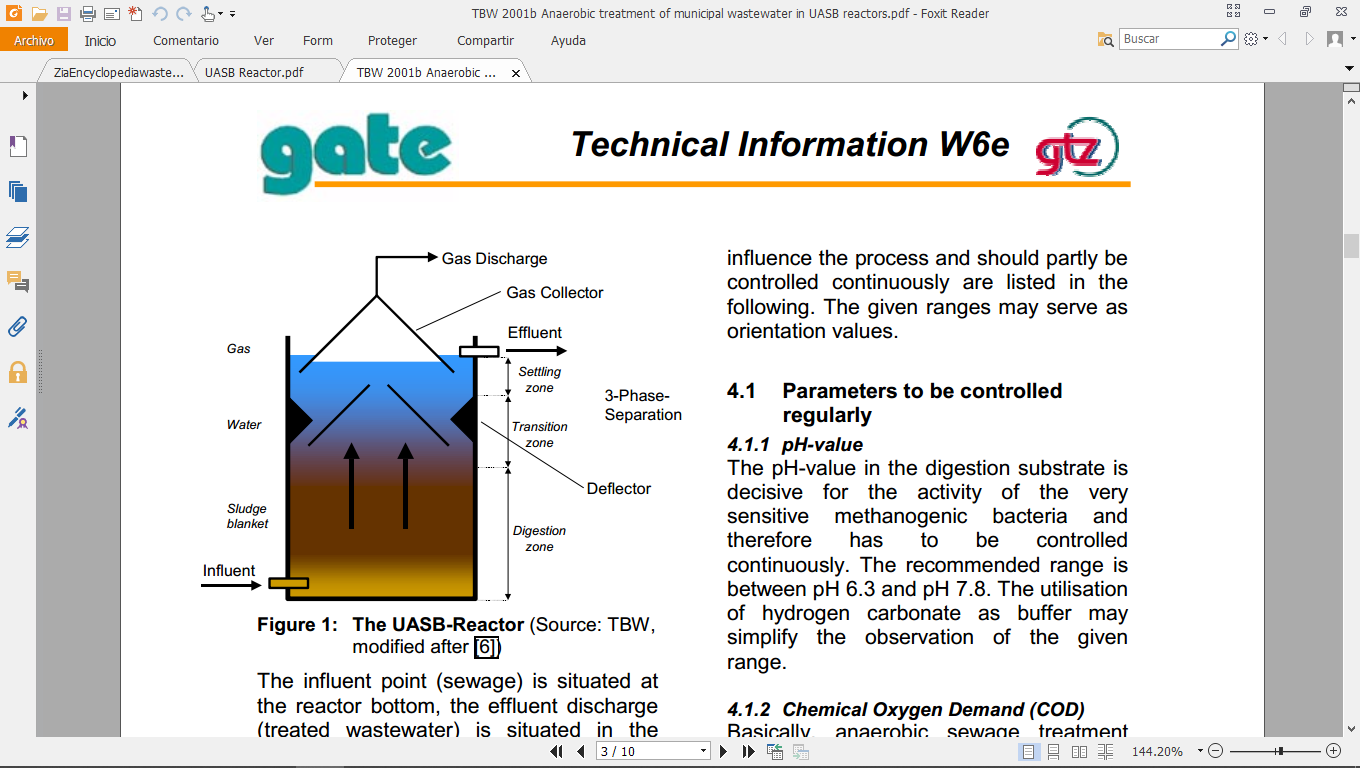

The most common and widely used anaerobic reactor is the UASB reactor. It is an attached, self-immobilized cell system, which consists of a bottom layer of packed sludge bed (sludge blanket) and an upper liquid layer, as shown in Fig. 8.

Fig. 8. Upfl ow anaerobic sludge blanket reactor.

In a UASB-reactor, the accumulation of influent suspended solids and bacterial activity and growth lead to the formation of a sludge blanket near the reactor bottom, where all biological processes take place. Two main features decisively influencing the treatment performance are the distribution of the wastewater in the reactor and the “3-phase-separation” of sludge, gas and water. While the sludge should remain in the reactor, the produced gas is collected before the purified water leaves the reactor.

The influent point (sewage) is situated at the reactor bottom; the effluent discharge (treated wastewater) is situated in the upper part of the reactor, thus forcing the entering sewage to follow an upflow regime and to get into contact with the sludge blanket in the reactor. Here, the organic matter in the sewage is subject to anaerobic degradation by the bacteria contained in the sludge blanket, with methanogenic (“methane building”) bacteria producing methane gas (CH4) during the degradation processes.

In order to prevent unwanted sludge discharge, separation devices (deflectors) are installed that prevent the further upward movement of the sludge and force it to sink back into the bed. The gas is collected in gas holders installed in the upper part of the reactor; for gas rising close to the reactor walls, an additional one may be installed.

Important operating parameters in anaerobic reactors

Different operating parameters such as pH, temperature, hydraulic retention time (HRT), and nutrients, among others, and their disturbances can manifest in case of industrial wastewaters treatment in anaerobic reactors, even under normal operational conditions. Some of these factors are discussed below.

pH

The optimum degradation is achieved when the pH value of wastewater in the digester is maintained between 6, 5 and 7, 5. In the initial period of fermentation, as large quantities of organic acids are produced by acidogens and acetogens, a drop in pH occurs inside the digester. This low pH condition inhibits methanogens and subsequently reduces methane production. As the digestion proceed, the pH increases owing to the conversion of organic nitrogen to NH4. When the methane production level is stabilized, the pH range remains buffered between 7, 2 and 7, 8.

Chemical Oxygen Demand (COD)

Anaerobic sewage treatment may be applied for low as well as for high COD-concentrations. Depending on the respective local conditions, the advantages of the anaerobic process do generally only become distinct at a concentration of > 250 mg COD/L and achieve an optimum at a concentration of > 400 mg COD/L.

Temperature

Methanogens are inactive at extremely high and low temperatures. Few psychrophilic methanogens have been discovered, which can grow at a temperature range of 4–6°C. Most of the methanogens can grow well from 25°C to 65oC temperatures. The optimum temperature for the growth of the mesophilic methanogens is 35–37°C. When the ambient temperature goes down to 10°C, gas production virtually stops. Satisfactory gas production takes place in the mesophilic range, from 30°C to 40°C.

Loading Rate

High organic loading rate may lead to acid accumulation and reduction of methane production. Similarly, if the plant is underfed, the gas production will also be low.

Retention time

The retention time depends on the growth rate of the microbial population and reactor configuration (attached cell or suspended cell system), waste strength, and waste composition.

Toxicity

The presence of toxicants in the wastewater, such as oxygen (lethal to obligate anaerobes), ammonia, chlorinated hydrocarbons, aromatic hydrocarbons, heavy metals, and long-chain fatty acids, among several others, may also result in occasional failures of anaerobic digesters. The presence of trace amount of metals (e. g., nickel, cobalt, molybdenum) also stimulates the growth of microbes. Excess volatile fatty acid (VFA) concentrations are reported to inhibit the growth of several microbial species. The undissociated forms of VFA can diffuse across the cell membrane and dissociate intracellularly, which results in reduction in growth rate.

· Advanced biotreatments

The quality of the final effluent from conventional biological treatment systems is highly dependent on the hydrodynamic conditions in the sedimentation tank and the settling characteristics of the sludge. Consequently, large volume sedimentation tanks offering several hours of residence time are required to obtain adequate solid/liquid separation. At the same time, close control of the biological treatment unit is necessary to avoid conditions that lead to poor settle ability and/or bulking of sludge. Very often, however, economic constraints limit such options. Even with such controls, further treatment such as filtration, carbon adsorption, etc. are needed for most applications of wastewater reuse.

Therefore, a solid/liquid separation method different from conventional methods is necessary.

There are advanced wastewater biotreatment that must be considered in accordance with various beneficial reuse purposes as well as the aspect of human and environmental health. This is especially important when the treated wastewater is aimed to use for the rehabilitation of urban creak and creation of water environment along it.

Application of membrane separation (micro- or ultrafiltration) techniques for biosolid separation can overcome the disadvantages of the sedimentation tank and biological treatment steps. The membrane offers a complete barrier to suspended solids and yields higher quality effluent.

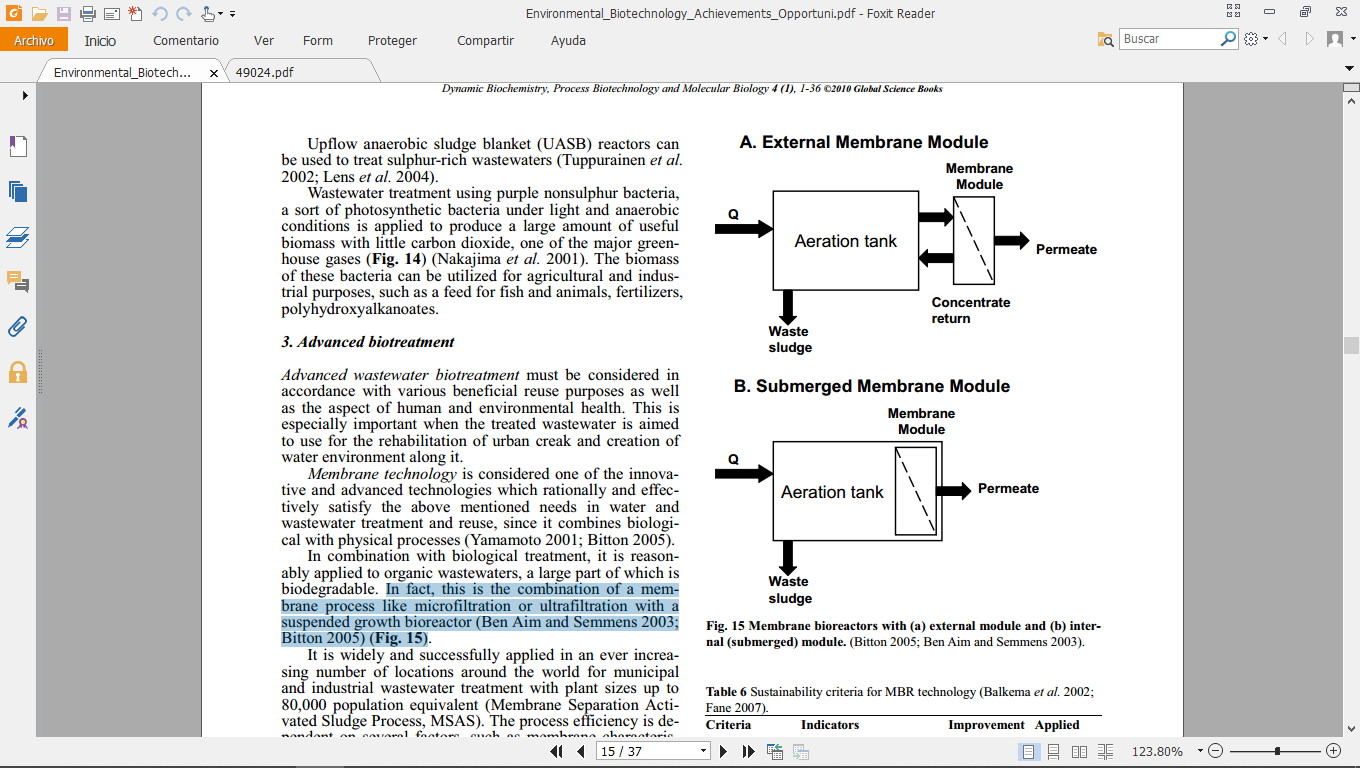

Membrane technology is considered one of the innovative and advanced technologies, which rationally and effectively satisfy the above-mentioned needs in water and wastewater treatment and reuse, since it combines biological with physical processes.

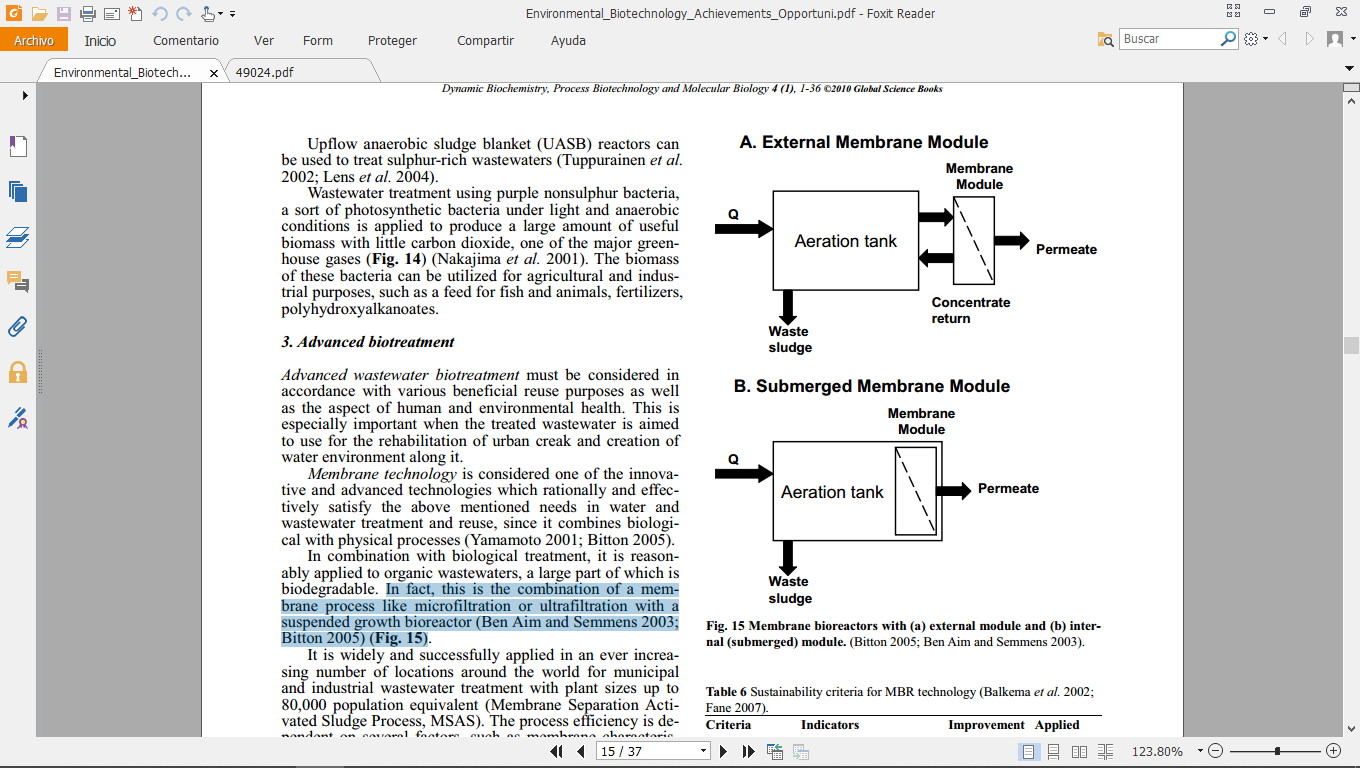

In combination with biological treatment, it is reasonably applied to organic wastewaters, a large part of which is biodegradable. In fact, this is the combination of a membrane process like microfiltration or ultrafiltration with a suspended growth bioreactor (Fig. 9).

Fig. 9. Membrane bioreactors with (A) external module and (B) internal (submerged) module.

There are two main process configurations of biomass rejection membrane bioreactors (MBRs), side-stream and internal (submerged).

The most widely used in municipal wastewater treatment membrane technology is the submerged type, where membrane modules are directly immersed in an aeration tank (Fig. 9 B). This aims to significantly reduce the energy consumption by eliminating a big circulation pump typically installed in a conventional membrane systems. Consequently, the operating costs for this configuration are lower.

MBRs can be operated aerobically or anaerobically for organic compounds and nutrients removal. The advantages of MBR systems over conventional biological systems include better effluent quality, smaller space requirements, and ease of automation. Specifically, MBRs operate at higher volumetric loading rates, which result in lower hydraulic retention times. The low retention times mean that less space is required compared to a conventional system. MBRs have often been operated with longer SRTs, which results in lower sludge production; but this is not a requirement, and more conventional SRTs have been used. The effluent from MBRs contains low concentrations of bacteria, total suspended solids, BOD, and phosphorus. This facilitates high-level disinfection. Effluents are readily discharged to surface streams or can be sold for reuse, such as irrigation.

The main advantages of biological processes in comparison with chemical oxidation are no need to separate colloids and dispersed solid particles before treatment, lower energy consumption, the use of open reactors, resulting in lower costs, and no need for waste gas treatment. However, in the cost analysis it is necessary to consider the costs of membrane cleaning and fouling control, eventual membrane replacement and the need for air scouring to control bacterial growth on the membranes.

The process efficiency is dependent on several factors, such as membrane characteristics, sludge characteristics, operating conditions. Thus, there is a need for process optimization considering the different interactions between the membrane performance and the process operating conditions.

|

|

|