|

Составьте аннотацию текста А.

|

|

|

|

4. Прочитайте следующие слова, обращая внимание на разные способы чтения буквосочетания "ch".

[tς] achieve; much; branch

[ς] machine

[k] mechanized; mechanization; mechanical; technology; characteristics

5. Прочитайте и запомните произношение следующих слов:

Automation, through, intervention, intelligence, automobile, digital, sequence, possess, artificial.

6. Прочитайте и переведите группы однокоренных слов:

automation – automatic – automated

to develop – developed – development

mechanics – mechanical - mechanized – mechanization

electron – electronic – electronics

to power – powered – powerful

to use – usage – used – useful

Сгруппируйте слова из списков А и В в синонимичные пары и переведите их.

| A | B |

| to use by means of to be capable of branch ability usage to possess | to be able to to have application to apply field with the help of capability |

Text B

Steam Engine

Long ago people noticed that steam has the power of moving things, and they began to wonder how steam could be made to work for them. The first steam-engine was made in ancient Egypt by Hero, a philosopher of Alexandria.

It consisted of a hollow globe, which could turn on a pair o pipes and was supplied with steam through one of them. The steam escaped from the globe to the outside air through two bent pipes facing tangentially in opposites directions at the ends of a diameter perpendicular to the axis. The globe revolved by reaction from the escaping steam. Hero’s engine described in his work “Pneumatica” was regarded merely as a toy. In fact, it was seventeen hundred years before anyone showed any further interest in the idea of a steam-engine.

The earliest steam-engine which found employment in industry was that of Thomas Savery in 1698. The engine was used in pumping mines and I raising water to supply houses and towns. A serious difficulty with this engine was that the height which it would lift water was limited by the pressure the boiler could bear.

There were even explosions, as the safety valve had not yet been invented. This was invented by the Frenchman Denis Papin, who was also the inventor of the piston.

The next step forward was taken by the English mechanic Thomas

Newcomen combined the ideas of Savery and Papin. It was he who designed an engine that could be used not only to pump water, but also to drive other machinery.

An even better steam- engine was built in Russia in 1765 by the brilliant mechanic Ivan Polzunov. One of the reasons why it was better was that it could be used for many purposes and not just for pumping water. Secondly, Polzunov’s engine had two cylinders. Hence, while the piston in one was going down, the piston in the other was rising. It was therefore the first continuous action engine.

|

|

|

The next inventor who helped to make the steam-engine what it is today was James Watt, a maker of instruments at the University of Glasgow. The legend is told is that Watt invented the modern steam-engine by watching the steam lift the lid of his boiling tea-kettle. This, of course, is not so. Watt began improving the steam-engine, when one of Newcomen’s engines was brought to his workshop for repairs. This was in 1763. By 1785 he had developed a greatly improved steam-engine, which found many more uses than earlier models had. This led to the Steam Age.

But the story of the steam-engine does not end with Watt. As progress with to the idea of Hero of Alexandria, his aeolipile which was in fact the first steam-turbine, using steam to produce rotary movement.

Перескажите текст B.

Подберите русские эквиваленты к следующим словам и словосочетаниям.

| A | B |

| 1. steam – engine 2. to consist of 3. hollow 4. to revolve 5. a pair of 6. at the ends 7. to supply 8. a serious difficulty 9. axis 10. machinery 11. inventor 12. piston 13. step forward 14. pressure 15. one of the reasons 16. to go down 17. many more use | a. гораздо больше применений; b. снабжать, обеспечивать c. ось d. вращаться e. состоять из f. изобретатель g. шаг вперед h. пара (чего-либо) i. механизмы j. опускать(ся) k. давление l. полый(пустой) m. на концах n. одна из причин o. паровой двигатель p. поршень q. серьезное затруднение |

3. Определите, какой частью речи является каждое слово из колонки A, и дайте его значение, взяв за основу значение слова с тем же корнем из колонки B:

| A | B | ||

| development | ??? | develop v. | развивать |

| use | ??? | use v. | использовать |

| inventor | ??? | invent v. | изобретать |

| production | ??? | produce v. | производить |

| social | ??? | society n. | общество |

| valuable | ??? | value n. | ценность |

| distant | ??? | distance n. | расстояние |

Подберите антонимы к данным словам.

| A | B |

| difficulty to lift strong to end first good active | to go down passive last to begin easiness weak bad |

Определите, какой частью речи являются следующие слова.

Переведите их:

Brilliant, continuous, merely, explosion, dominate, materialize, development, invention, inventor, improvement.

6. Переведите, обращая внимание на местоимения some, any, no, every и их производные:

1. Have you any interesting books on this problem?

2. Here are some letters for you.

3. Any student can make this simple experiment.

4. Somebody works in the laboratory every evening.

5. Nobody uses this instrument.

|

|

|

6. She never says anything about her Institute.

7. No laboratory assistant works in this laboratory in the evening.

8. Somebody gave me this book yesterday.

9. Is there anybody in this room?

10. Every student of our group can do this work without any effort.

11. No information was received from the article.

UNIT 5

Ultrasonic Welding

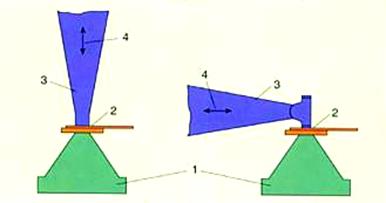

When bonding material through ultrasonic welding, the energy required comes in the form of mechanical vibrations. The welding tool (sonotrode) couples to the part to be welded and moves it in longitudinal direction. The part to be welded on remains static. Now the parts to be bonded are simultaneously pressed together. The simultaneous action of static and dynamic forces causes a fusion of the parts without having to use additional material. This procedure is used on an industrial scale for linking both plastics and metals (figure).

Figure: Differences in the process for welding plastics and metals with ultrasonics

1. Anvil

2. Parts to be welded

3. Sonotrode

4. Ultrasonic oscillation

Ultrasonic welding of plastics is a state-of-the-art technology that has been in use for many years. When welding thermoplastics, the thermal rise in the bonding area is produced by the absorption of mechanical vibrations, the reflection of the vibrations in the connecting area, and the friction of the surfaces of the parts. The vibrations are introduced vertically. In the contraction area, frictional heat is produced so that material plasticizes locally, forging an insoluble connection between both parts within a very short period of time.

The prerequisite is that both working pieces have a near equivalent melting point. The joint quality is very uniform because the energy transfer and the released internal heat remains constant and is limited to the joining area. In order to obtain an optimum result, the joining areas are prepared to make them suitable for ultrasonic bonding. Besides plastics welding, ultrasonics can also be used to rivet working parts or embed metal parts into plastic.

Whereas in plastic welding, high-frequency vertical vibrations (20 to 70kHz) are used to increase the temperature and plastify the material, the joining of metals is an entirely different process. Unlike in other processes, the parts to be welded are not heated to melting point, but are connected by applying pressure and high-frequency mechanical vibrations.

In contrast to plastics welding, the mechanical vibrations used during ultrasonic metal welding are introduced horizontally.

|

|

|