|

Handling the rear shock absorber

|

|

|

|

AND GAS CYLINDER

WARNING

WARNING

This rear shock absorber and gas cylinder contain highly compressed nitrogen gas. Before handling the rear shock absorber or gas cylinder, read and make sure you understand the following information. The manufacturer cannot be held responsible for property damage or personal injury that may result from improper handling of the rear shock absorber and gas cylinder.

• Do not tamper or attempt to open the rear shock absorber or gas cylinder.

• Do not subject the rear shock absorber or gas cylinder to an open flame or any other source of high heat. High heat can cause an explosion due to excessive gas pressure.

• Do not deform or damage the rear shock absorber or gas cylinder in any way. If the rear shock absorber, gas cylinder or both are damaged, damping performance will suffer.

EAS00689

DISPOSING OF A REAR SHOCK

ABSORBER AND GAS CYLINDER

Gas pressure must be released before dispos-ing of a rear shock absorber and gas cylinder. To release the gas pressure, drill a 2 ~ 3 mm (0.08 ~ 0.12 in) hole through the gas cylinder at a point 15 ~ 20 mm (0.59 ~ 0.79 in) from its end as shown.

WARNING

WARNING

Wear eye protection to prevent eye damage from released gas or metal chips.

4 - 90

REAR SHOCK ABSORBER CHAS

REAR SHOCK ABSORBER CHAS

EAS00693

REMOVING THE REAR SHOCK ABSORBER

ASSEMBLY

1. Stand the scooter on a level surface.

WARNING

WARNING

Securely support the scooter so that there is no danger of it falling over.

NOTE:

Place the scooter on a suitable stand so that the rear wheel is elevated.

Н Remove:

rear shock absorber bolts 1

NOTE:

When removing the rear shock absorber bolts 1, hold the swingarm so that it does not drop down.

О Remove:

rear shock absorber assembly

EAS00696

CHECKING THE REAR SHOCK ABSORBER

ASSEMBLY AND GAS CYLINDER

П Check:

rear shock absorber rod

Bends/damage → Replace the rear shock absorber assembly.

rear shock absorber

Gas leaks/oil leaks → Replace the rear shock absorber assembly.

spring

Damage/wear → Replace the rear shock absorber assembly.

gas cylinder

Damage/gas leaks → Replace the rear shock absorber assembly.

bushings

Damage/wear → Replace.

dust seal

Damage/wear → Replace.

bolts

Bends/damage/wear → Replace.

4 - 91

REAR SHOCK ABSORBER CHAS

REAR SHOCK ABSORBER CHAS

INSTALLING THE REAR SHOCK

ABSORBER ASSEMBLY

Р Lubricate:

spacer

bearings

Recommended lubricant

Lithium-soap-based grease

С Install:

|

|

|

rear shock absorber assembly 1

bolt (rear side) 2

| • nut 3 | T.R. | 53 Nm (5.3 m · kg, 38 ft · lb) |

3. Install:

• lock washer 1 New

• bolt (front side) 2

T.

R.

68 Nm (6.8 m · kg, 49 ft · lb)

NOTE:

Т When installing the bolt 1, hold the swing-arm so that it does not drop down.

Т Bend the lock washer 2 tab along a flat side of the bolt 1.

4 - 92

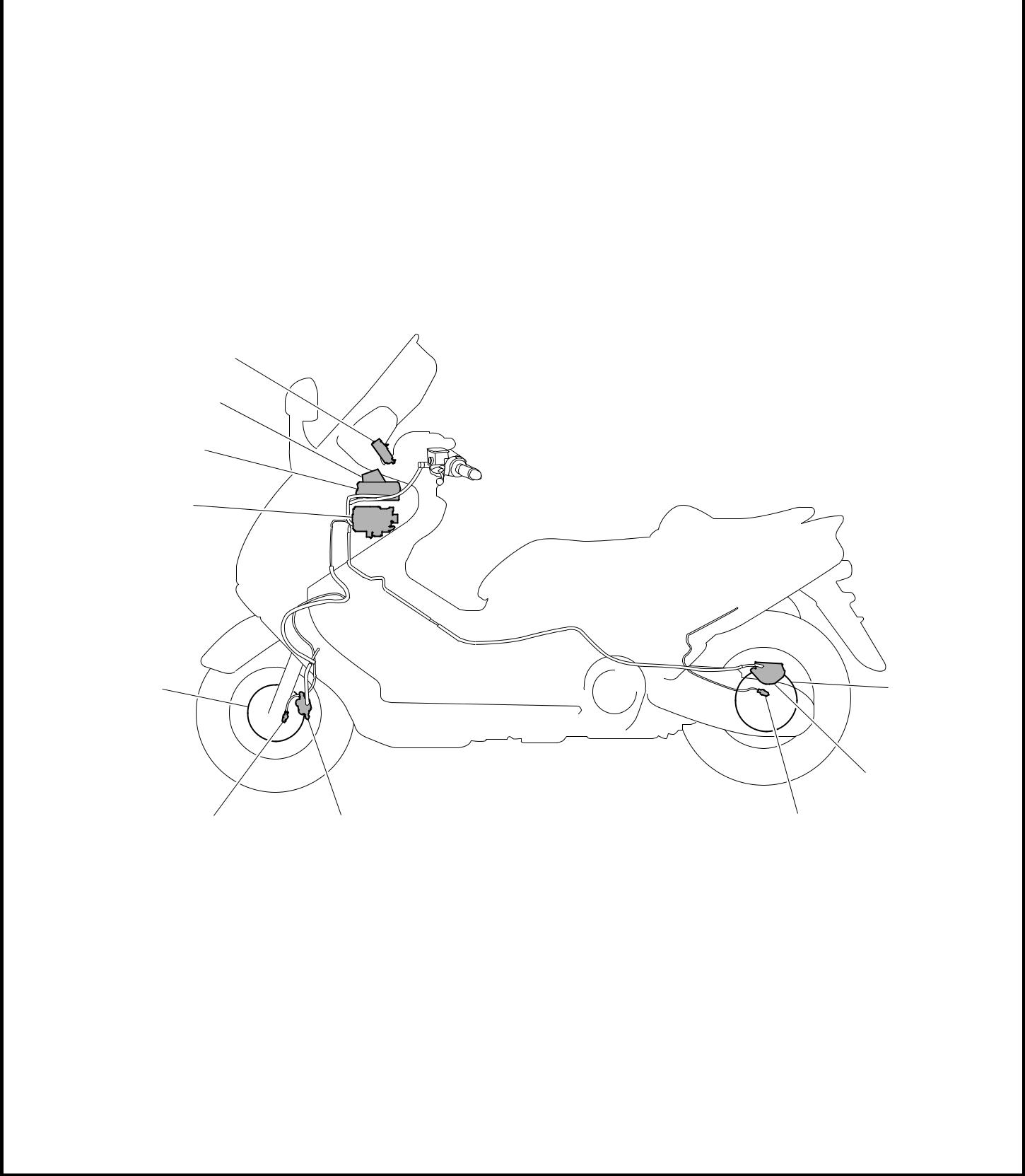

| ANTI-LOCK BRAKE SYSTEM (XP500A) | CHAS | |

| ANTI-LOCK BRAKE SYSTEM (XP500A) | ||

| EAS00882 | ||

| ABS COMPONENTS | ||

| 1 ABS warning light | 8 Front brake caliper | |

| 2 Fail-safe relay | 9 Front wheel sensor | |

| 3 Electronic control unit (ECU) | 0 Front disc rotor | |

| 4 Hydraulic unit | ||

| 5 Rear disc rotor | ||

| 6 Rear brake caliper | ||

| 7 Rear wheel sensor |

4 - 93

ANTI-LOCK BRAKE SYSTEM (XP500A) CHAS

ANTI-LOCK BRAKE SYSTEM (XP500A) CHAS

4 - 94

| 4 - 95 |

| A | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B/Y B/L | Gy B | B/Y | L/W Y/L Y/G Gy/G W/Y B/Y | B/W Y/B L | R/W R/B O | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B/L | Br | Br | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Lg G/R Br/W P/W Y B/L L/Y Y/R W/B R/L G/B B | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| W | W | R | Y/B | Y/B | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| W | W | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| W | W | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| WIRE HARNESS | GRIP WARMER | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SUB-WIRE HARNESS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| W | W | W | W | W | W | B | R | B | X | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| R/B | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| W | W | W | R | B | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Z | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R | H | B/Y | O | O | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R | B | Y | B/L | G/R | G/R B/L | Br/L | Br/L | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (GREEN) | B | B | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R | R | L/W | G/R | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R | R | R | L/W | R/L | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B/W B | R/G | R/G | B | B | R/B | R/B | [ | WIRE HARNESS | DC TERMINAL | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| R | R | SUB-WIRE HARNESS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Y/L G/L R/W | R/W Lg Y/L | L/R | Br/R | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ON | L/W R/W | B/L | Br/W | Br/W B/L | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| N | O | R/L | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| OFF | G | I | (BLACK) | C | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R/G R/W Y/L | R | R | W/R | R/L | (GREEN) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| P | G/W | Br/W | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G/LB B/W | Br/L | Br/L | B | J | L/W | R/B | L/Y | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G/Y | B | P/W | Y | Y | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B/W | L/W | R/L L/Y | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R/W | W/R Lg | Lg | W/R | Gy/G | ^ | B | B | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L/Y | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Br/L | B/L | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G/Y W/R | R/B L/W | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L/R | B | R/L | W | P/W | B/L P/W L | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L | R/W | R/L | O/B | R/B R/L | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | B | (BLUE) | \ | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | L | (BLACK) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L/W | M | R/L | G | (BLACK) | (BLACK) | WIRE HARNESS | HEADLIGHT | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| K | (BLACK) | SUB-WIRE HARNESS 1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| P | R/B | R/B | R/L | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R/G | R/W | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B G/W | G B | ] R/L O/B | G/B R/L | Gy/G | a B/L | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B/W BB | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Br/W | R/L B | B | B | G | G | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R | L/G | R/L | (GREEN) | (GREEN) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G/B G/B | R/L | R/L | B | B | B | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L/G R/G | L/G | B | B | R/L | B | (BLACK) | (BLACK) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Y/B | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| W | L | Gy/G B/L | HEADLIGHT | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R/W | WIRE HARNESS | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R/G | R | (BLACK) | (BLACK) | SUB-WIRE HARNESS 2 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L/G | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | Lg | B/L | bL Y B/L | E | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| W/Y | L | L | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Br/L | Br | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | Q | G/W | R/W | Y | Y | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R/Y | R/B | Y/R | B/L | (BLACK) | Ch | Br/G | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Lg | Y/G | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R/W | Ch Br/W Dg | Dg Br/W Ch | R | S | T | B/W | W/B | c | L/R | L/R | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | B/L | (GREEN) | (GREEN) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | Br/L L/Y | V | B | B | Y/L | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| U | Y/G | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Br/R | (BLACK) | (BLACK) | L Y/G B/L | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F | (BLUE) | L | WIRE HARNESS | TURN SIGNAL | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L/R | L/R | SUB-WIRE HARNESS 1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R/W R/B G/Y | G/Y R/B R/W | B | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | B | Lg | B | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R/G R/L | Br B G/W | L/W B Br | F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L/R Br/R R/Y Br/L | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (BROWN) | (BROWN) | (BLUE) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Х B | R | L/R Br/W R/W Br | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | B | Ch | Dg | Br | G/Y | Dg | Br/G | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Br/W | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | R/L R/G | Br/L R/Y Br/R L/R | L/R | L/R | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | Br R/W Br/W L/R | Y/B | A | Y/B | (GREEN) | (GREEN) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Br | A | Br | WIRE HARNESS | TURN SIGNAL | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SUB-WIRE HARNESS 2 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | Br/L | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | m | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Br/L | Br/L | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | B | Br/Y | Br/Y | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B B | Lg | B/W W | WG | B/W | Y | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Br/Y | Br/W W/Y G/W W/B P/W W/R | B | BW | B/W Sb | R/W | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (GREEN) | (GREEN) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| • | Br | Sb B | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | B | Br/Y | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B/W | Br/R | Lg W/R | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | B | R/YR/Y | n | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B B | Br | Br | R/W | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Lg | WW | f Gy W | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R/Y | o | W B | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| q | Br/W | Br/R | d | Sb | Sb | B | B | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| s | r | r | Br/Y | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L/B | Br | P | Br | P | Br | L | Br/Y | Lg | Lg | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| B/W Lg | R/Y | W/B | (BLACK) | (BLACK) | R/W | Y/R | B | B | W/R | W/R | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| W/B | P | P | Br/W | B | W | W | g Gy W | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L Y/R | B | Br/W | W B | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L/B | B | B | B | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | W/Y | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | G/W | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| t | R/Y | L/B | P | Br/W | Br G/Y | B | B | p | W/B | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| u v | w | x | L | L | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ¶G/L | R/W | G/Y G Y | Y G L/Y | y | (BLACK) | (BLACK) | Br/W | W/RW/B R | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| R/G | Y/L | G Lg | L | Y | Dg | Ch | W/R | h | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Br Ch Dg | Dg Ch B/Y | PASS | NR | B | e | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Br | Y/B | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| N | R | B | R/W W/B | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Я | ® | B P Br/W | Br/W P B | NL | Br | P/W Br/W W/R R | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| … | R/Y L/B | L/B R/Y | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ґ µ є ж | ш Ў | (BLUE) | (BLUE) | B/W | P/W BR | R/W | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| k | j | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| © | ™ | Y | G | B | Ch | Dg | R/W | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| OFF | Y/R | P/W | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ON | Y/B | Y | R R | R/W | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| (BLACK) | R | R | R | R | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Y/B | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B/W | L | W G | G W | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Br/Y | Br/Y | i | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L/R | F | L/R | Br/Y | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ch Dg Y W/R | R/W R/G G | YG | L | W | W | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Y/L | Ch | Dg | Y/B Br/Y | L | (BLACK) | G | G | R/W B | B/W R/W | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| G/L | L | Lg B/W | C | D | Br | Br | ||||||||||||||||||||||||||||||

| E | F | |||||||||||||||||||||||||||||||||||

| Y | G | B/W | ||||||||||||||||||||||||||||||||||

| l | ||||||||||||||||||||||||||||||||||||

| Y | G | Br/G | Br/G | L | L | |||||||||||||||||||||||||||||||

| Y | B | G | B | L/R | L | L | ||||||||||||||||||||||||||||||

| † | Br/G | Br/G | z Dg Ch | |||||||||||||||||||||||||||||||||

| з | е | G/Y | ||||||||||||||||||||||||||||||||||

| L/R | E L/R | L/R | Ј § ў | L/R | (BLUE) | (BLUE) | B/W | B/W | ||||||||||||||||||||||||||||

| ў | Br/G | B | Br/G | B | L | |||||||||||||||||||||||||||||||

| L | ||||||||||||||||||||||||||||||||||||

| B | C | B | B | B | ||||||||||||||||||||||||||||||||

| L/R | Br | Br | L/R | B | B | { | } } ~ | Y | L | L/R G/Y | l | L | L | ||||||||||||||||||||||||

| B | B | |||||||||||||||||||||||||||||||||||

| B | G | G | B | Ch | Dg | Dg Ch | L | B | ||||||||||||||||||||||||||||

| (BLUE) | (BLUE) | |||||||||||||||||||||||||||||||||||

| B | B | B | ||||||||||||||||||||||||||||||||||

| B | D | B | B | |||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

| CIRCUIT | EAS00884 |

| DIAGRAM |

| ANTI-LOCK BRAKE SYSTEM (XP500A) CHAS |

ANTI-LOCK BRAKE SYSTEM (XP500A) CHAS

ANTI-LOCK BRAKE SYSTEM (XP500A) CHAS

4 Main switch

9 ABS control unit fuse B Signaling system fuse

У Battery

У ABS motor fuse

У Main fuse

Ф Starting circuit cut-off relay 2

Ф Starting circuit cut-off relay 1

11 Start switch

12 Engine stop switch

И Front brake light switch

Й ECU (engine) d ABS test coupler e ECU (ABS)

f Front wheel sensor g Rear wheel sensor h Fail-safe relay

i Hydraulic unit

y Rear brake light switch } Tail/brake light

® Multi-function display … ABS warning light

4 - 96

ANTI-LOCK BRAKE SYSTEM (XP500A) CHAS

ANTI-LOCK BRAKE SYSTEM (XP500A) CHAS

CAUTIONS FOR OPERATION

ABS warning light:

К When the main switch is set to “ON”, the ABS warning light comes on for 2 seconds, then goes off.

|

|

|

К If the ABS warning light comes on while riding, stop the vehicle, and then set the main switch to “OFF”, then set the main switch to “ON”. The ABS operation is normal if the ABS warning light comes on for 2 seconds, then off.

К If the rear wheel is raced with the vehicle on the centerstand, the ABS warning light may flash or come on. If this occurs, set the main switch to “OFF”, then back to “ON”. The ABS operation is normal if the ABS warning light comes on for 2 seconds, then goes off.

К The ABS operation is normal if the ABS warning light flashes.

К Even if the ABS warning light remains on and does not go off or if it comes on after riding, con-ventional braking performance of the vehicle is maintained.

ABS function:

A brake system in which the hydraulic control has been performed by the ABS alerts a rider that the wheels had a tendency to lock by generating a reaction-force pulsating action in the brake levers. When the ABS is activated, the grip between the road surface and tires is close to the limit. The ABS cannot prevent wheel lock* on slippery surfaces such as ice, when it is caused by engine braking, even if the ABS is activated.

The ABS is not designed to shorten the braking distance or improve the cornering performance.

Depending on the road conditions, the braking distance may be longer compared to that of vehi-cles not equipped with an ABS. Therefore, ride at a safe speed and keep a safe distance between yourself and other vehicles.

The braking of the vehicle, even in the worst case, is principally executed when the vehicle is advancing straight ahead. During a turn, sudden braking is liable to cause a loss of traction of the tires. Even vehicles equipped with an ABS cannot be prevented from falling over if braked suddenly.

The ABS does not work when the main switch is set to “OFF”. The conventional braking function can be used.

Л Wheel lock: A condition that occurs when the rotation of one or both of the wheels has stopped but the vehicles continues to travel.

4 - 97

ANTI-LOCK BRAKE SYSTEM (XP500A) CHAS

ANTI-LOCK BRAKE SYSTEM (XP500A) CHAS

TROUBLESHOOTING

EAS00881

|

|

|