|

6-3-2 Double heads Spacing Calibration

|

|

|

|

6-3-2 Double heads Spacing Calibration

If you are using 2 heads, you have to implement this calibration. Generally speaking, as the second heads is far away from the guide rail, its printing quality will be inferior than the first head. If the testing result is opposite, youЎЇd better check the installation of the head and the head holder. Sometimes result from the mechanical precision, itЎЇs very hard to conform the 2 heads. At that moment, you should assure one head is splendid firstly.

Calibrating of the vertical spacing of the 2 heads: for the machine with one head, the hardware calibration is finished till now. But for 2 heads machine, you have to calibrating the vertical spacing.

Senior menu modelЁ¤calibrationЁ¤vertical spacing calibratingЁ¤enter. See picture below:

Caution: the triangle above is printed by the first head, the trapezoid below is printed by the second head. The spacing between the lowest line of the triangle and the top line of the trapezoid is the same as the spacing between the headsЎЇ own nozzles. Simply speaking, if you cannot distinguish the limit of the triangle and trapezoid, calibration is unnecessary.

Generally, after malposition and incline calibration, the heads are horizontal. You only have to paralleled move the second head close to the first one.

When you move the second head, there may be left-right incline. At that moment, you have to retest the malposition and recalibrating.

6-3-3 Color Calibrating

Software adjusting: including stepping, both-direction, left-align, right-align etc.

Stepping adjusting:

1Ј© normal model:

menuЁ¤calibrationЁ¤mediaЁ¤print

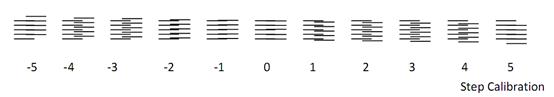

This simple operation only print one line. The default stepping is 4 PASS, the same as 1 PASS. Every bar has a number below. Check which one is best and read the number. Then add the number you got to the default number. Finally, input the calculated number. Reach the second place after decimal point.

2Ј©senior model:

senior menu modelЁ¤calibration-> mediaЁ¤choose PASS numberЁ¤print .

Under senior model, there are different media and PASS number. YouЎЇd better adjust the 4 PASS firstly and then 3, 6, 8 or other PASS number for the same media. Different media have different stepping parameter. Before printing, affirm the media is consent to the default media name.

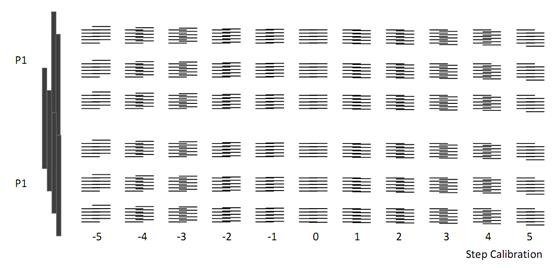

Attention please, under this model, the machine will continuously print 10 circulation. For 4 PASS printing, there are 3 lines. The 1st line is consequent of 1st PASS and 2nd PASS, the 2nd line is consequent of 1st PASS and 3rd PASS. The 3rd line is consequent of 1st PASS and 4th PASS. If the stepping is incorrect, the error of 3rd line is the most apparent. Besides, as there are 10 circulation, the printing process needs a long time. But we can find out stepping error easily and see whether the precision of feeding have periodic variation. For 6 PASS, there are 5 lines and 7 lines for 8 PASS.

|

|

|

The lateral test bar print in color K and M. If thereЎЇs no physic malposition between the 2 heads, the stepping of these 2 colors will be consistent to each other. YouЎЇd better pay attention to the left color blocks of the test bar. If the head is not vertical, there will be spaces in the left color blocks.

You can click the cancel button to stop printing.

If you feel very difficult to affirm the origin position, check the left one and right one. The origin position is close to the one with less apparent fault. And you can also check it in different media width, as the mechanic precision will be checked at the same time.

Caution: if the difference between the machineЎЇs stepping and real printing is very big, check the 1st line firstly. Maybe the data needs a big modification. The machine allows 50% modification every time. When the 1st line origin position is ok, slightly adjust the 3rd line origin position.

The stepping of one head is half of the two headЎЇs.

3Ј©both-direction adjustment:

|

|

|