|

Checking the clutch plates

|

|

|

|

The following procedure applies to all of the clutch plates.

Ъ Check:

clutch plate

Damage → Replace the clutch plates as a set.

Ъ Measure:

clutch plate warpage

(with a surface plate and thickness gauge

1)

Out of specification → Replace the clutch plates as a set.

Maximum clutch plate warpage Clutch plate 1

Mm (0.0039 in) Clutch plate 2

Mm (0.0079 in)

5 - 52

CLUTCH ENG

CLUTCH ENG

CHECKING THE CLUTCH SPRINGS AND

CLUTCH DAMPER SPRINGS

The following procedure applies to all of the clutch springs.

Ы Check:

clutch spring

Damage → Replace the clutch springs as a set.

Ы Measure:

clutch spring free length a

Out of specification → Replace the clutch spring.

Clutch spring limit 25.4 mm (1.00 in)

Ь Measure:

clutch damper spring 1 b

Out of specification → Replace the clutch damper spring 1.

Clutch damper spring 1 limit

Mm (0.11 in)

Ю Measure:

clutch damper spring 2 c

Out of specification → Replace the clutch damper spring 2.

Clutch damper spring 2 limit 4.40 mm (0.17 in)

EAS00284

CHECKING THE CLUTCH HOUSING

Я Check:

clutch housing dogs

Damage/pitting/wear → Deburr the clutch housing dogs or replace the clutch housing.

NOTE:

Pitting on the clutch housing dogs will cause erratic clutch operation.

5 - 53

CLUTCH ENG

CLUTCH ENG

EAS00285

CHECKING THE CLUTCH BOSS

А Check:

clutch boss splines

Damage/pitting/wear → Replace the clutch boss.

NOTE:

Pitting on the clutch boss splines will cause erratic clutch operation.

EAS00286

CHECKING THE PRESSURE PLATE AND

THRUST PLATE

Х Check:

pressure plate

thrust plate

Cracks/damage → Replace.

CHECKING THE WEIGHT

Ц Check:

weight

Cracks/wear/scaling/chipping → Replace. Out of specification → Replace.

Weight outside diameter 16.0 mm (0.63 in) <Limit>: 15.5 mm (0.61 in)

ASSEMBLING THE CLUTCH

Ч Lubricate:

friction plates

clutch plates

(with the recommended lubricant)

Recommended lubricant

Engine oil

5 - 54

CLUTCH ENG

CLUTCH ENG

Ш Install:

clutch boss

primary drive gear

clutch boss nut 1

Ш Tighten:

clutch boss nut

| T.R. | 90 Nm (9.0 m · kg, 65 ft · lb) |

NOTE:

While holding the clutch boss 2 with the clutch holding tool 3, tighten the clutch boss nut.

|

|

|

Clutch holding tool 90890-04086, YM-91042

Ъ Install:

clutch damper spring 1 1

clutch plate 2 2

friction plate 3

clutch plate 1 4

И Engine side

5 - 55

CLUTCH ENG

CLUTCH ENG

INSTALLING THE CLUTCH

Ы Install:

clutch assembly 1

clutch assembly nut 2

T.

R.

65 Nm (6.5 m · kg, 47 ft · lb)

NOTE:

ЬAlign the a and b during reassembly.

ЬWhile holding the clutch assembly with the rotor holding tool 3, tighten the clutch assembly nut.

Rotor holding tool 90890-01235, YU-01235

5 - 56

V-BELT AUTOMATIC TRANSMISSION ENG

V-BELT AUTOMATIC TRANSMISSION ENG

V-BELT AUTOMATIC TRANSMISSION

V-BELT CASE

| Order | Job/Part | Q’ty | Remarks |

| Removing the V-belt case | Remove the parts in the order listed. | ||

| Muffler | Refer to “ENGINE REMOVAL”. | ||

| V-belt case cover 1 | |||

| V-belt case cover 2 | |||

| V-belt case air filter cover | |||

| V-belt case air filter element | |||

| Lead holder | |||

| V-belt case | |||

| V-belt case gasket | |||

| Bearing retainer | |||

| Bearing | |||

| Circlip | |||

| Oil seal | |||

| Bearing | |||

| For installation, reverse the removal pro- | |||

| cedure. | |||

5 - 57

V-BELT AUTOMATIC TRANSMISSION ENG

V-BELT AUTOMATIC TRANSMISSION ENG

V-BELT AND PRIMARY/SECONDARY SHEAVE

*1 Shell BT grease 3®

*2 BEL-RAY assembly lube®

*2 BEL-RAY assembly lube®

| Order | Job/Part | Q’ty | Remarks | ||

| Removing the V-belt and primary/ | Remove the parts in the order listed. | ||||

| secondary sheave | |||||

| V-belt case air filter element (left) | Refer to “WATER PUMP” in chapter 6. | ||||

| Primary sheave nut | |||||

| Spacer | |||||

| O-ring | Refer to “REMOVING THE PRIMARY | ||||

| Primary sheave assembly | SHEAVE ASSEMBLY, SECONDARY | ||||

| Primary fixed sheave | SHEAVE ASSEMBLY AND V-BELT” | ||||

| Secondary sheave nut | and “INSTALLING THE PRIMARY | ||||

| Secondary sheave assembly | SHEAVE ASSEMBLY, SECONDARY | ||||

| Collar | SHEAVE ASSEMBLY AND V-BELT”. | ||||

| O-ring | |||||

| V-belt | |||||

| Right crankcase cover | |||||

|

|

|

5 - 58

V-BELT AUTOMATIC TRANSMISSION ENG

V-BELT AUTOMATIC TRANSMISSION ENG

*1 Shell BT grease 3®

*2 BEL-RAY assembly lube®

*2 BEL-RAY assembly lube®

| Order | Job/Part | Q’ty | Remarks | |||

| V-belt case air duct joint clamp | Loosen. | Refer to “INSTALLING | ||||

| V-belt case air duct | THE PRIMARY SHEAVE | |||||

| ASSEMBLY, SECOND- | ||||||

| ARY SHEAVE ASSEM- | ||||||

| BLY AND V-BELT”. | ||||||

| Plate | ||||||

| V-belt case air duct seal | ||||||

| For installation, reverse the removal pro- | ||||||

| cedure. | ||||||

5 - 59

V-BELT AUTOMATIC TRANSMISSION ENG

V-BELT AUTOMATIC TRANSMISSION ENG

* BEL-RAY assembly lube®

| Order | Job/Part | Q’ty | Remarks | ||

| Disassembling the primary sheave | Remove the parts in the order listed. | ||||

| Cam | Refer to “DISASSEMBLING THE PRI- | ||||

| Slider | MARY SHEAVE” and “ASSEMBLING | ||||

| Weight | THE PRIMARY SHEAVE”. | ||||

| Primary sliding sheave | |||||

| Collar | |||||

| For assembly, reverse the disassembly | |||||

| procedure. | |||||

5 - 60

V-BELT AUTOMATIC TRANSMISSION ENG

V-BELT AUTOMATIC TRANSMISSION ENG

* BEL-RAY assembly lube®

| Order | Job/Part | Q’ty | Remarks | ||

| Disassembly the secondary sheave | Remove the parts in the order listed. | ||||

| Secondary sheave spring seat nut | Refer to “DISASSEMBLING THE SEC- | ||||

| ONDARY SHEAVE” and “ASSEMBLING | |||||

| THE SECONDARY SHEAVE”. | |||||

| Upper spring seat | |||||

| Compression spring | |||||

| Spring seat | |||||

| Secondary sliding sheave | Refer to “ASSEMBLING THE SECOND- | ||||

| Oil seal | ARY SHEAVE”. | ||||

| O-ring | |||||

| Guide pin | |||||

| Secondary fixed sheave | For assembly, reverse the disassembly | ||||

| procedure. | |||||

5 - 61

V-BELT AUTOMATIC TRANSMISSION ENG

V-BELT AUTOMATIC TRANSMISSION ENG

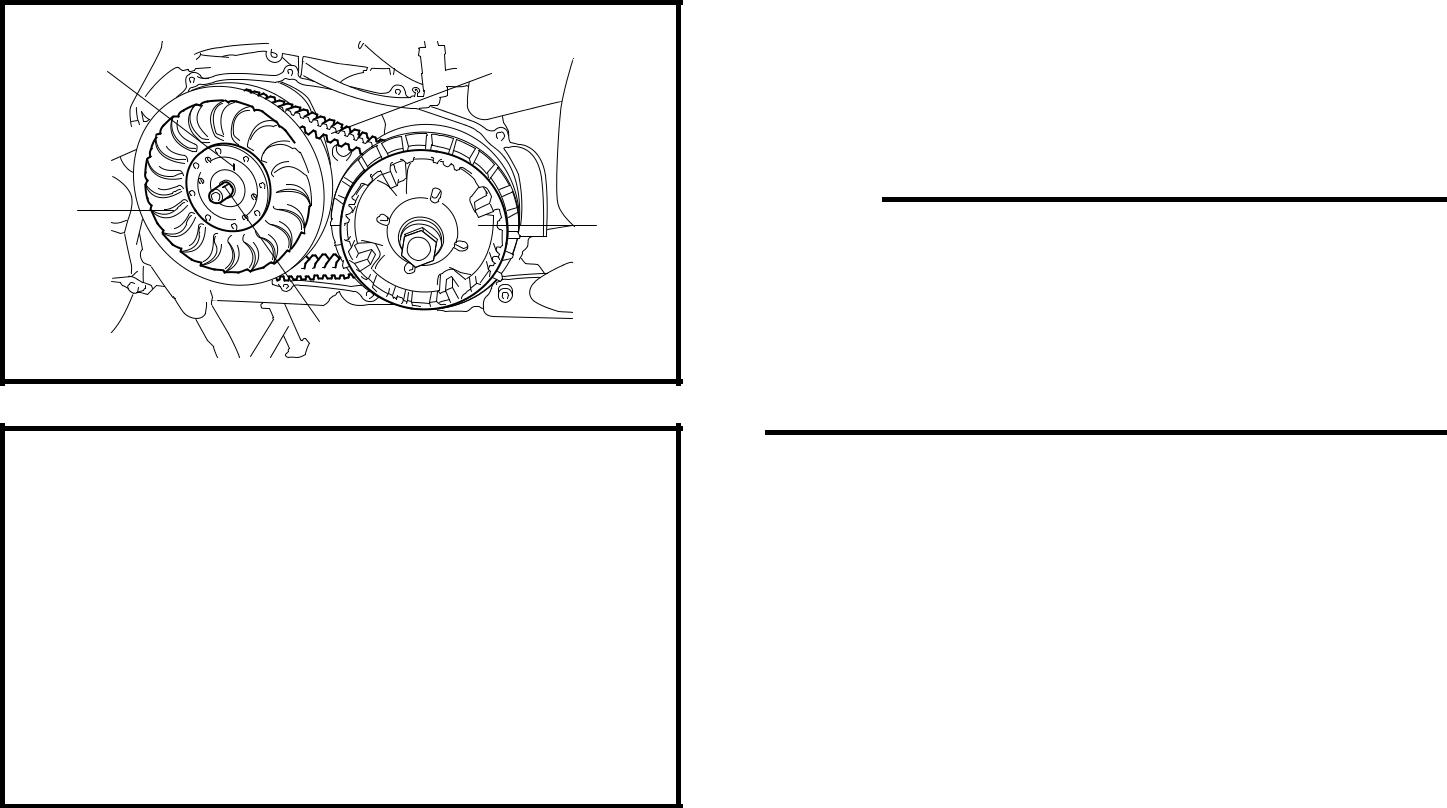

| REMOVING THE PRIMARY SHEAVE | ||||

| ASSEMBLY, SECONDARY SHEAVE | ||||

| ASSEMBLY AND V-BELT | ||||

| 1. Remove: | ||||

| • primary sheave nut 1 | ||||

| • secondary sheave nut 2 | ||||

| NOTE: | ||||

| While | holding the primary | and secondary | ||

| sheave with the sheave holder, loosen the nut. | ||||

| Sheave holder | ||||

| 90890-01481 | ||||

|

|

|

| 2. Install: | |

| • bolts 1 | |

| NOTE: | |

| Insert M6 bolts (more than 45 mm (1.77 in)) | |

| into the holes of the secondary sheave assem- | |

| bly, and then tighten the bolts to open the sec- | |

| ondary sheave assembly. |

| 3. Remove: | |||

| a | • secondary sheave assembly 1 | ||

| • primary sheave assembly 2 | |||

| • V-belt 3 | |||

| NOTE: | |||

| • Before removal, apply a and b alignment | |||

| marks. | |||

| b | • Align these marks during reassembly. | ||

| • Remove the primary sliding sheave, second- | |||

| ary sheave assembly and V-belt together. | |||

| 4. Remove: | |||

| • primary fixed sheave 1 |

5 - 62

V-BELT AUTOMATIC TRANSMISSION ENG

V-BELT AUTOMATIC TRANSMISSION ENG

|

|

|