|

7-2-1 Print Head check and cleaning

|

|

|

|

7-2-1 Print Head check and cleaning

| Daily check of the head before turning on the machine | After starting the machine, print a total head status testing bar and save it. | Testing of head 1, feed in media 2, set the starting point(white edge) 3, when the machine is standing by, carry out one testing procedure.

Cleaning of head 1, when standing by, press clean button once.

|

| Test of head before printing | Every time before printing, check the head whether they are jammed or surface dry. | |

| Cleaning of the head when printing | If the head jammed when printing, suspend the project and clean the head right away. | |

| Daily check of the head after work | After finishing the last image, print a total head status testing bar and contrast with the daily starting one. If the head jammed, manually clean it right away, until get the same testing bar as the daily starting one. |

7-2-2 Head Protective Plate Cleaning

Every day, before turning on and off the machine, clean the head protective plate, in order to assure there are no dirt on the head.

Every day, before turning on and off the machine, clean the head protective plate, in order to assure there are no dirt on the head.

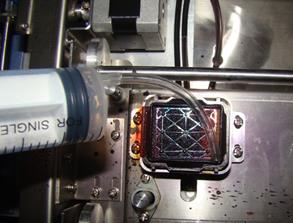

(1) Inject some cleaning liquid to the plate with the cylinder.

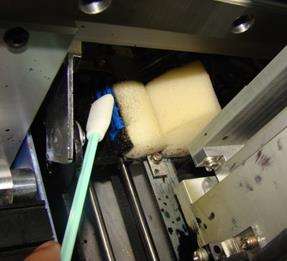

ЈЁ2Ј© Clean the plate with cotton swab, both the cotton mat and circumference.

ЈЁ2Ј© Clean the plate with cotton swab, both the cotton mat and circumference.

7-2-3 Scraping Sheet Cleaning

7-2-3 Scraping Sheet Cleaning

Wipe both sides of the scraping sheet with cotton swab, which had been immersed in cleaning liquid.

7-2-4 Printing Test Calibration

If the heating system, cooling fans and print heads are all in good status, start printing the test bar. The test bar can be formed by lines, characters and color block. See the picture below. The lines and characters must be black(C80, M80ЈY80ЈK100). The color block can be formed by single color blockЈЁKЎўCЎўMЎўYЎўLCЎўLMЈ© or mixed color block.

Correct printed picture:

Correct printed picture:

Color process problem:

Color process problem:

If the test bar looks like the picture above, the heads need calibrating again. See 6-3.

Broken ink drop of single color:

Broken ink drop of single color:

See picture above, if there are white line or white block in the black block, clean the print head and reprint test bar. See 5-2-2.

All the colors turn white:

All the colors turn white:

See picture above, if every color turns white or there are white lines in every color, recalibrate the feeding in speed of media (6-3-2) and stepping volume (6-3-5). If it doesnЎЇt work, reset the heating temperature. If it still doesnЎЇt work, you have to change the media. Relative information see 5-1-6.

7-2-5 Wasted Ink Bucket Disposition

Get out the barrel of wasted ink when you finish daily work. Handle the wasted ink according to local law and regulations. If not, the wasted ink may flux and damage the machine.

7-2-6 Guide Rail Oiled

Grease both the up and down groove of the guide rail. And there should be 5-6 grease position of the whole rail.

Grease both the up and down groove of the guide rail. And there should be 5-6 grease position of the whole rail.

|

|

|

| |||||

| |||||

| |||||

7-2-7 Mechanical Movement Wheel Oiled

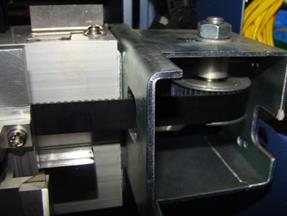

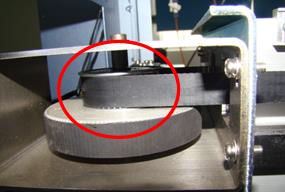

As the guide rail, the belt wheel needs to be lubricated regularly, in order to affirm the smooth and steady of the movement. The positions need lubricating as below:

As the guide rail, the belt wheel needs to be lubricated regularly, in order to affirm the smooth and steady of the movement. The positions need lubricating as below:

Belt wheel

| |||

| |||

Synchronic wheel

|

X-axial synchronic wheel

|

Y-axial synchronic wheel

Y-axial synchronic wheel

Y-axial holder

Y-axial holder

| |||

| |||

7-2-8 Media Holder Cleaning

|

Clean it with cotton swab, which should

been immersed in cleaning liquid.

|

7-3 Weekly Check and Maintenance

7-3-1 Print Head Cleaning

|

(1) Turn off the machine.

Move the carriage to the left.

|

(2) Add some cleaning liquid to the cotton swab and lightly wipe the surface and circumference of the print head.

| |||

| |||

|

|

|