|

After adjusting the throttle cable free play, turn the handlebar to the right and to the left to ensure that this does not cause the engine idling speed to change.

|

|

|

|

▲▲▲▲▲▲▲▲▲▲▲ ▲▲▲▲▲▲▲▲▲ ▲▲▲▲▲▲▲▲▲▲▲▲

Ш Install:

left side cover

center cover

Refer to “SIDE COVER MOULDINGS AND

LEG SHIELD”.

CHECKING THE SPARK PLUGS

The following procedure applies to all of the spark plugs.

U Remove:

center cover

side cover (left and right)

inner fender

Refer to “SIDE COVER MOULDINGS AND

LEG SHIELD”.

V Disconnect:

spark plug caps

W Remove:

spark plugs

CAUTION:

Before removing the spark plugs, blow away any dirt accumulated in the spark plug wells with compressed air to prevent it from falling into the cylinders.

Й Check:

spark plug type Incorrect → Change.

Spark plug type (manufacturer)

CR7E (NGK)

3 - 25

CHECKING THE SPARK PLUGS/

CHECKING THE IGNITION TIMING

CHK

ADJ

ADJ

К Check:

electrode 1

Damage/wear → Replace the spark plug.

insulator 2

Abnormal color → Replace the spark plug. Normal color is a medium-to-light tan color.

К Clean:

spark plug

(with a spark plug cleaner or wire brush)

К Measure:

spark plug gap a

(with a wire thickness gauge) Out of specification → Regap.

Spark plug gap

0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

Л Install:

spark plug

T.

R.

13 Nm (1.3 m · kg, 9.4 ft · lb)

NOTE:

Before installing the spark plug, clean the spark plug and gasket surface.

М Connect:

spark plug caps 10.Install:

Inner fender

side cover (left and right)

center cover

Refer to “SIDE COVER MOULDINGS AND

LEG SHIELD”.

EAS00062

CHECKING THE IGNITION TIMING

NOTE:

Prior to checking the ignition timing, check the wiring connections of the entire ignition sys-tem. Make sure that all connections are tight and free of corrosion.

Remove:

center cover

side cover (left and right)

left footrest board

1Refer to “SIDE COVER MOULDINGS AND

LEG SHIELD”.

Remove:

timing plug 1

3 - 26

CHECKING THE IGNITION TIMING/

MEASURING THE COMPRESSION PRESSURE

CHK

ADJ

ADJ

3. Install:

• timing light 1

(onto the spark plug lead of cylinder #1)

Timing light

YM-33277-B

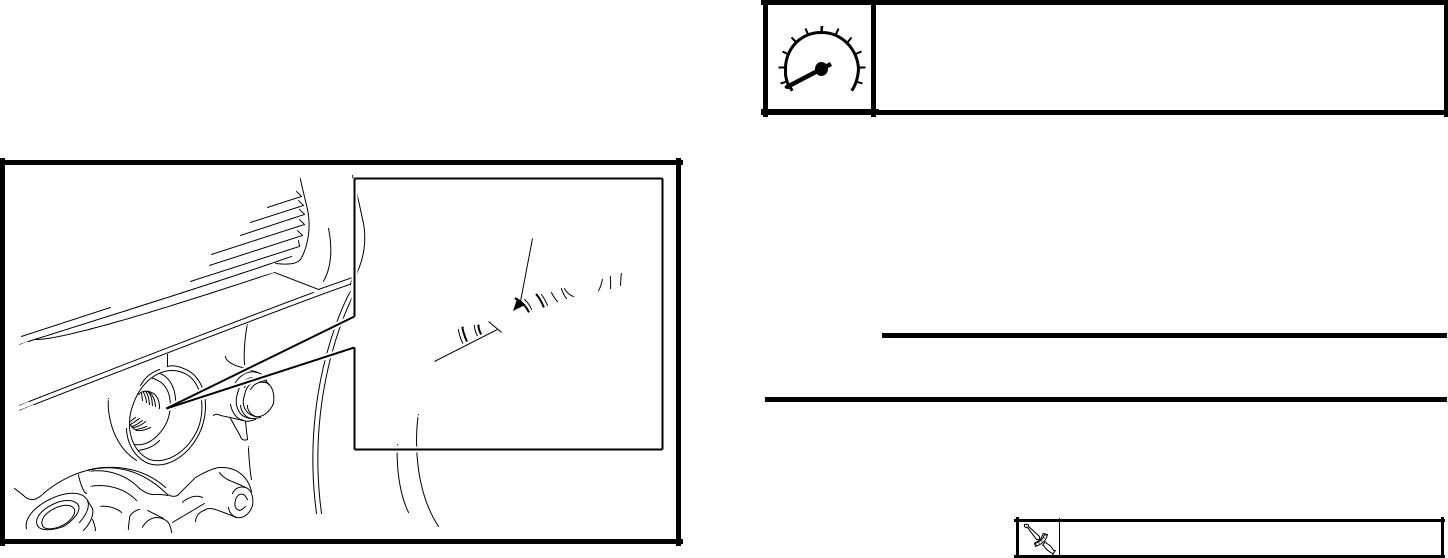

| 4. Check: | |||

| • ignition timing | |||

| ▼▼▼▼▼▼▼▼▼▼▼ ▼▼▼▼▼▼▼▼▼ ▼▼▼▼▼▼▼▼▼▼▼▼ | |||

| a. Start the engine, warm it up for several min- | |||

| utes, and then let it run at the specified | |||

| engine idling speed. | |||

| Engine idling speed | |||

| 1,100 ~ 1,300 r/min | |||

| b. Check that the stationary pointer a is within | |||

| the firing rang b on the A.C. magneto. | |||

| a | Incorrect firing range → Check the ignition | ||

| system. | |||

| NOTE: | |||

| b | The ignition timing is not adjustable. | ||

| ▲▲▲▲▲▲▲▲▲▲▲ ▲▲▲▲▲▲▲▲▲ ▲▲▲▲▲▲▲▲▲▲▲▲ | |||

| 5. | Install: | ||

| • timing plug | T.R.8 Nm (0.8 m · kg, 5.8 ft · lb) | ||

| 6. | Install: | ||

| • left footrest board | |||

| • side cover (left and right) | |||

| • center cover | |||

| Refer to “SIDE COVER MOULDINGS AND | |||

| LEG SHIELD”. |

|

|

|

EAS00065

MEASURING THE COMPRESSION

PRESSURE

The following procedure applies to all of the cylinders.

NOTE:

Insufficient compression pressure will result in a loss of performance.

3 - 27

CHK

CHK

MEASURING THE COMPRESSION PRESSURE ADJ

О Remove:

footrest board (left and right)

inner fender

Refer to “SIDE COVER MOULDINGS AND

LEG SHIELD”.

О Measure:

valve clearance

Out of specification → Adjust.

Refer to “ADJUSTING THE VALVE

CLEARANCE”.

О Start the engine, warm it up for several min-utes, and then turn it off.

О Disconnect:

spark plug cap

О Remove:

spark plug

CAUTION:

Before removing the spark plugs, use com-pressed air to blow away any dirt accumu-lated in the spark plug wells to prevent it from falling into the cylinders.

П Install:

compression gauge 1

Compression gauge 90890-03081, YU-33223

Extension 90890-04082

Р Measure:

compression pressure

Out of specification → Refer to steps (c) and (d).

Compression pressure at 360 r/min (at sea level)

Minimum 1,200 kPa

(12.0 kg/cm2, 170.7 psi) Standard

KPa

(14.0 kg/cm2, 199.1 psi) Maximum

KPa

(15.7 kg/cm2, 223.3 psi)

3 - 28

CHK

CHK

MEASURING THE COMPRESSION PRESSURE ADJ

▼▼▼▼▼▼▼▼▼▼▼ ▼▼▼▼▼▼▼▼▼ ▼▼▼▼▼▼▼▼▼▼▼▼

С Set the main switch to “ON”.

С With the throttle wide open, crank the engine until the reading on the compression gauge stabilizes.

|

|

|

WARNING

WARNING

|

|

|