|

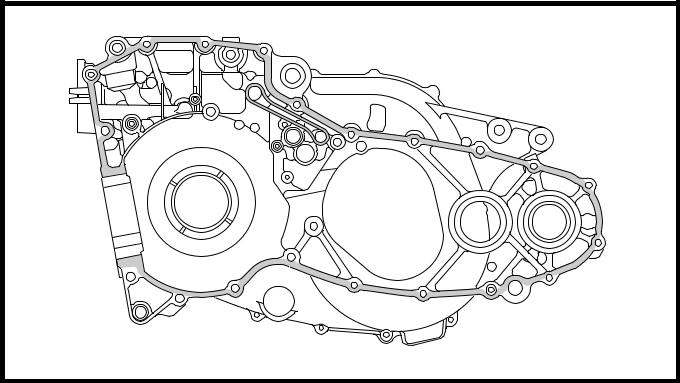

Installing the crankshaft main

|

|

|

|

JOURNAL BEARINGS

У Attach:

crankshaft main journal bearings

NOTE:

Attach the crankshaft main journal bearing to the plane bearing installer 1.

Plane bearing installer 90890-04139

Ф Install:

crankshaft main journal bearings 2

NOTE:

14 Align the projection a on the bearing with the projection b on the crankcase.

15 Place an iron 3 plate beneath the crankcase and press fit until the end of the plain bearing installer touches the iron plate.

INSTALLING THE CONNECTING RODS

И Install:

big end bearings 1

NOTE:

Й Align the projection a of the big end bear-ings with the notches b in the connecting rod cap.

Й Install each big end bearing in its original place.

К Install:

connecting rods

NOTE:

Л The stamped “Y” mark a on the connecting rods should face towards the left side of the crankcase.

Л Install each connecting rod in its original place.

5 - 80

CRANKCASE AND CRANKSHAFT ENG

CRANKCASE AND CRANKSHAFT ENG

М Install:

connecting rod cap

NOTE:

Be sure that the characters a on the side of the cap and connecting rod are aligned.

П Tighten:

nuts (connecting rod cap)

T.

R.

16 Nm (1.6 m · kg, 11 ft · lb) + 90°

NOTE:

Apply molybdenum disulfide grease to the rod cap bolt threads and nut surfaces.

▼▼▼▼▼▼▼▼▼▼▼ ▼▼▼▼▼▼▼▼▼ ▼▼▼▼▼▼▼▼▼▼▼▼

Р Replace the connecting rod bolts and nuts with new ones.

CAUTION:

Tighten the connecting rod bolts using the plastic-region tightening angle method. Always install new bolts and nuts.

С Clean the connecting rod bolts and nuts.

С Tighten the connecting rod nuts with speci-fied torque.

С Put a mark 1 on the corner of the connect-ing rod nut 2 and the connecting rod 3.

С Tighten the nut further to reach the speci-fied angle (90°).

WARNING

WARNING

When the nut is tightened more than the specified angle, do not loosen the nut and then retighten it.

Replace the bolt with a new one and per-form the procedure again.

CAUTION:

Т Do not use a torque wrench to tighten the nut to the specified angle.

Т Tighten the nut until it is at the specified angles.

NOTE:

When using a hexagonal nut, note that the angle from one corner to another is 60°.

▲▲▲▲▲▲▲▲▲▲▲ ▲▲▲▲▲▲▲▲▲ ▲▲▲▲▲▲▲▲▲▲▲▲

5 - 81

|

|

|

CRANKCASE AND CRANKSHAFT ENG

CRANKCASE AND CRANKSHAFT ENG

У Install:

balancer connecting rod

connecting rod cap

T.

R.

60 Nm (6.0 m · kg, 43 ft · lb)

CAUTION:

Х When tightening the nuts be sure to use an F-type torque wrench.

Х Without pausing, tighten to full torque specification. Apply continuous torque 57 ~ 63 Nm (5.7 ~ 6.3 m · kg, 41 ~ 45 ft · lb). Once you reach 57 Nm (5.7 m · kg, 41 ft · lb) DO NOT STOP TIGHTENING until final torque is reached. If the tightening is inter-rupted 57 ~ 63 Nm (5.7 ~ 6.3 m · kg, 41 ~ 45 ft · lb) loosen the nut to less than 57 Nm (5.7 m · kg, 41 ft · lb) and start again.

INSTALLING THE CRANKSHAFT

П Install:

crankshaft assembly 1

balancer piston cylinder 2

T.

R.

58 Nm (5.8 m · kg, 42 ft · lb)

CAUTION:

To avoid scratching the crankshaft and to ease the installation procedure, apply grease onto the oil seal lips and apply engine oil onto each bearing.

EAS00418

ASSEMBLING THE CRANKCASE

Р Thoroughly clean all the gasket mating sur-faces and crankcase mating surfaces.

5 - 82

CRANKCASE AND CRANKSHAFT ENG

CRANKCASE AND CRANKSHAFT ENG

2. Apply:

• sealant

(onto the crankcase mating surfaces)

Yamaha bond No. 1215 90890-85505

Sealant (Quick Gasket®) ACC-11001-05-01

NOTE:

Do not allow any sealant to come into contact with the oil gallery.

3. Install:

• dowel pins

• left crankcase

5 - 83

TRANSMISSION ENG

TRANSMISSION ENG

TRANSMISSION

| Order | Job/Part | Q’ty | Remarks |

| Removing the transmission | Remove the parts in the order listed. | ||

| Left crankcase | Refer to “CRANKCASE AND CRANK- | ||

| SHAFT”. | |||

| Secondary shaft | |||

| Main axle | |||

| Primary driven gear | |||

| First pinion gear | |||

| Washer | |||

| Drive axle | |||

| First wheel gear | |||

| Circlip | |||

| Bearing | |||

| Oil seal | |||

| For installation, reverse the removal pro- | |||

| cedure. | |||

5 - 84

TRANSMISSION ENG

TRANSMISSION ENG

REMOVING THE TRANSMISSION

С Remove:

left crankcase

Refer to “CRANKCASE AND CRANK-SHAFT”.

С Remove:

secondary shaft 1

main axle 2

drive axle 3

primary driven gear 4

first wheel gear 5

first pinion gear

EAS00425

CHECKING THE TRANSMISSION

У Measure:

main axle runout

(with a centering device and dial gauge) Out of specification → Replace the main axle.

Maximum main axle runout

Mm (0.0031 in)

Ц Measure:

drive axle runout

(with a centering device and dial gauge) Out of specification → Replace the drive axle.

|

|

|

Maximum drive axle runout

Mm (0.0031 in)

● Measure:

• secondary shaft runout

(with a centering device and dial gauge) Out of specification → Replace the second-ary shaft.

|

|

|