|

Intake air temperature sensor resistance

|

|

|

|

2.21 ~ 2.69 k Ω at 20 °C (68 °F)

| WARNING | ||||||

| • Handle the intake air temperature sensor | ||||||

| with special care. | ||||||

| • Never subject the intake air temperature sen- | ||||||

| sor to strong shocks. If the intake air temper- | ||||||

| ature sensor is dropped, replace it. | ||||||

| 4. Is the intake air temperature sensor OK? | ||||||

| Open or short circuit in wiring har- | Repair or replace if there is an open or short circuit. | |||||

| ness. | Between sensor coupler and ECU (engine) coupler | |||||

| black/blue – black/blue | ||||||

| brown/white – brown/white | ||||||

| Connected condition of connector | If there is a malfunction, repair it and connect it | |||||

| Inspect the coupler for any pins | securely. | |||||

| that may have pulled out. | Intake air temperature sensor coupler | |||||

| Check the locking condition of the | Main wiring harness ECU (engine) coupler | |||||

| coupler. |

7 - 17

| FUEL INJECTION SYSTEM | FI | ||||||||

| Fault code No. | Symptom No normal signal is received from the O2 sensor. | ||||||||

| Used diagnostic code No. -- | |||||||||

| Order | Inspection operation item and | Operation item and countermeasure | Reinstatement | ||||||

| probable cause | method | ||||||||

| Installed state of O2 sensor | Check the installed area for looseness or pinching. | As the returning | |||||||

| method start | |||||||||

| Connected state of connector | Check the coupler for any pins that may have pulled | ||||||||

| method, start and | |||||||||

| O2 sensor coupler | out. Check the locking condition of the coupler. If | ||||||||

| warm up the | |||||||||

| Main wiring harness ECU | there is a malfunction, repair it and connect it | ||||||||

| engine until the | |||||||||

| (engine) coupler | securely. | ||||||||

| coolant tempera- | |||||||||

| Open or short circuit in wiring har- | Repair or replace if there is an open or short circuit. | ture rises over | |||||||

| ness | Between O2 sensor coupler and ECU (engine) cou- | 60 °C (140 °F). | |||||||

| pler | Then, maintain the | ||||||||

| black/blue – black/blue | engine speed at | ||||||||

| gray/green – gray/green | 2,000 r/min to | ||||||||

| red/blue – red/blue | 3,000 r/min until | ||||||||

| black – black | the warning light | ||||||||

| goes off. When the | |||||||||

| Check fuel pressure | Refer to “CHECKING THE FUEL PUMP OPERA- | ||||||||

| warning light goes | |||||||||

| TION”. | |||||||||

| off, the reset oper- | |||||||||

| Defective O2 sensor | Replace if defective. | ation is finished. | |||||||

|

|

|

7 - 18

| FUEL INJECTION SYSTEM | FI | |||||||||||||

| Fault code No. | Symptom | The scooter has overturned. | ||||||||||||

| Used diagnostic code No. 08 (lean angle cut-off switch) | ||||||||||||||

| Order | Inspection operation item and | Operation item and countermeasure | Reinstatement | |||||||||||

| probable cause | method | |||||||||||||

| Defective lean angle cut-off switch | Replace if defective. | Reinstated by turn- | ||||||||||||

| 1. | Remove the lean angle cut-off switch from the | ing the main switch | ||||||||||||

| scooter. | ON (however, the | |||||||||||||

| 2. | Connect the lean angle cut-off switch coupler to | engine cannot be | ||||||||||||

| the wire harness. | restarted unless | |||||||||||||

| 3. | Connect the pocket tester (DC 20 V) to the lean | the main switch is | ||||||||||||

| angle cut-off switch coupler as shown. | first turned OFF). | |||||||||||||

| Positive tester probe→blue1 | ||||||||||||||

| Negative tester probe→yellow/green2 | ||||||||||||||

| 4. When turn the lean angle cut-off switch approx. | ||||||||||||||

| 45°, the voltage reading change from 0.9 V to | ||||||||||||||

| 4.1 V. | ||||||||||||||

| 5. Is the emergency stop switch OK? | ||||||||||||||

| The scooter has overturned. | Raise the scooter upright. | |||||||||||||

| Installed condition of the lean | Check the installed area for looseness or pinching. | |||||||||||||

| angle cut-off switch | ||||||||||||||

| Connected condition of connector | If there is a malfunction, repair it and connect it | |||||||||||||

| Inspect the coupler for any pins | securely. | |||||||||||||

| that may have pulled out. | Lean angle cut-off switch coupler | |||||||||||||

| Check the locking condition of the | Main wiring harness ECU (engine) coupler | |||||||||||||

| coupler. | ||||||||||||||

| Fault code No. | Symptom | Malfunction detected in the primary lead of the ignition coil. | ||||||||||||

| Used diagnostic code No. 30 (ignition coil) | ||||||||||||||

| Order | Inspection operation item and | Operation item and countermeasure | Reinstatement | |||||||||||

| probable cause | method | |||||||||||||

| Defective ignition coil (test the pri- | Replace if defective. | Reinstated by | ||||||||||||

| mary and secondary coils for conti- | Refer to “IGNITION SYSTEM” in chapter 8. | starting the engine | ||||||||||||

| nuity) | and operating it at | |||||||||||||

| idle. | ||||||||||||||

| Open or short circuit in lead. | Repair or replace if there is an open or short circuit. | |||||||||||||

| In case of multiple | ||||||||||||||

| Between ignition coil coupler and ECU (engine) cou- | ||||||||||||||

| cylinder open or | ||||||||||||||

| pler/ main harness | short circuit in lead, | |||||||||||||

| orange – orange | ||||||||||||||

| make sure to turn | ||||||||||||||

| red/black – red/black | ||||||||||||||

| ON and OFF the | ||||||||||||||

| Connected condition of connector | If there is a malfunction, repair it and connect it | main switch after | ||||||||||||

| Inspect the coupler for any pins | securely. | each time of crank- | ||||||||||||

| that may have pulled out. | Ignition coil primary side coupler – orange | ing. | ||||||||||||

| Check the locking condition of the | Main wiring harness ECU (engine) coupler | |||||||||||||

| coupler. | ||||||||||||||

| 7 - 19 |

|

|

|

|

|

|

| FUEL INJECTION SYSTEM | FI | |||||||||

| Fault code No. | Symptom | Engine idling speed is too high. | ||||||||

| Used diagnostic code No. 01 (throttle position sensor) | ||||||||||

| Order | Inspection operation item and | Operation item and countermeasure | Reinstatement | |||||||

| probable cause | method | |||||||||

| Stuck FID valve detected. | Inspect the throttle body. | Reinstated by | ||||||||

| Replace if defective. | starting the engine | |||||||||

| Refer to “THROTTLE BODY”. | and operating it at | |||||||||

| idle for about 5 | ||||||||||

| Defective throttle fully closed. | Inspect the throttle body. | |||||||||

| minutes. Do not | ||||||||||

| Replace if defective. | ||||||||||

| turn the throttle | ||||||||||

| Refer to “THROTTLE BODY”. | ||||||||||

| grip. | ||||||||||

| Fault code No. | Symptom | Open or short circuit detected in the lean angle cut-off switch. | ||||||||

| Used diagnostic code No. 08 (lean angle cut-off switch) | ||||||||||

| Order | Inspection operation item and | Operation item and countermeasure | Reinstatement | |||||||

| probable cause | method | |||||||||

| Defective lean angle cut-off switch | Replace if defective. | Reinstated by turn- | ||||||||

| Refer to “Fault code No. 30”. | ing the main switch | |||||||||

| ON. | ||||||||||

| Open or short circuit in wiring har- | Repair or replace if there is an open or short circuit. | |||||||||

| ness. | Between switch coupler and ECU (engine) coupler | |||||||||

| black/blue – black/blue | ||||||||||

| yellow/green – yellow/green | ||||||||||

| blue – blue | ||||||||||

| Connected condition of connector | If there is a malfunction, repair it and connect it | |||||||||

| Inspect the coupler for any pins | securely. | |||||||||

| that may have pulled out. | Lean angle cut-off switch coupler | |||||||||

| Check the locking condition of the | Main wiring harness ECU (engine) coupler | |||||||||

| coupler. | ||||||||||

|

|

|

7 - 20

| FUEL INJECTION SYSTEM | FI | ||||||||||||||||||||||||||||

| Fault code No. | Symptom The ECU (engine) is unable to monitor the battery voltage. | ||||||||||||||||||||||||||||

| Used diagnostic code No. 09 (fuel system voltage) | |||||||||||||||||||||||||||||

| Order | Inspection operation item and | Operation item and countermeasure | Reinstatement | ||||||||||||||||||||||||||

| probable cause | method | ||||||||||||||||||||||||||||

| Malfunction in ECU (engine) | Fuel injection system relay is on. | Reinstated by | |||||||||||||||||||||||||||

| starting the engine | |||||||||||||||||||||||||||||

| Open or short circuit in the wiring | Repair or replace if there is an open or short circuit. | ||||||||||||||||||||||||||||

| and operating it at | |||||||||||||||||||||||||||||

| harness. | Between starting circuit cut-off relay (fuel injection | ||||||||||||||||||||||||||||

| idle. | |||||||||||||||||||||||||||||

| system relay), fuel pump, fuel injector (#1, #2) | |||||||||||||||||||||||||||||

| red/blue – red/blue | |||||||||||||||||||||||||||||

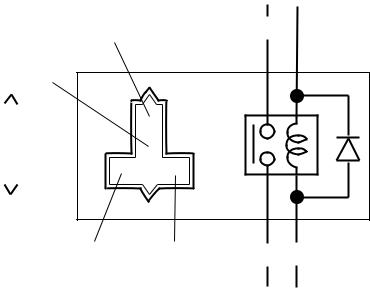

| Malfunction or open circuit in fuel | Replace if defective. | ||||||||||||||||||||||||||||

| injection system relay | 1. Disconnect the fuel injection system relay from | ||||||||||||||||||||||||||||

| the wire harness. | |||||||||||||||||||||||||||||

| 2. Connect the pocket tester (Ω Ч 1) and battery | |||||||||||||||||||||||||||||

| (12 V) to the fuel injection system relay terminals | |||||||||||||||||||||||||||||

| as shown. | |||||||||||||||||||||||||||||

| Positive battery terminal→red/black1 | |||||||||||||||||||||||||||||

| Negative battery terminal→blue/yellow2 | |||||||||||||||||||||||||||||

| Positive tester probe→red/blue3 | |||||||||||||||||||||||||||||

| Negative tester probe→red/blue4 | |||||||||||||||||||||||||||||

| R/L | |||||||||||||||||||||||||||||

| R/B | |||||||||||||||||||||||||||||

| R/L | |||||||||||||||||||||||||||||

| R/L | |||||||||||||||||||||||||||||

| R/B | L/Y | ||||||||||||||||||||||||||||

| R/L | L/Y | ||||||||||||||||||||||||||||

| 3. Does the fuel injection system relay have conti- | |||||||||||||||||||||||||||||

| nuity between red/blue and red/blue? | |||||||||||||||||||||||||||||

| Connected condition of connector | If there is a malfunction, repair it and connect it | ||||||||||||||||||||||||||||

| Inspect the coupler for any pins | securely. | ||||||||||||||||||||||||||||

| that may have pulled out. | Fuel injection system relay coupler | ||||||||||||||||||||||||||||

| Check the locking condition of the | ECU (engine) coupler | ||||||||||||||||||||||||||||

| coupler. | |||||||||||||||||||||||||||||

|

|

|

7 - 21

| FUEL INJECTION SYSTEM | FI | ||||||||||

| Fault code No. | Symptom | Error is detected while reading or writing on EEPROM (CO adjustment value). | |||||||||

| Used diagnostic No. 60 (EEPROM improper cylinder indication) | |||||||||||

| Order | Inspection operation item and | Operation item and countermeasure | Reinstatement | ||||||||

| probable cause | method | ||||||||||

| Malfunction in ECU (engine) | Execute diagnostic code 60 | Reinstated by turn- | |||||||||

| • Check the faulty cylinder. (If there are multiple | ing the main switch | ||||||||||

| cylinders, the number of the faulty cylinders | ON. | ||||||||||

| appear alternately at 2-second intervals.) | |||||||||||

| • | Readjust the CO of the displayed cylinder. | ||||||||||

| Refer to “ADJUSTING THE EXHAUST GAS | |||||||||||

| VOLUME” in chapter 3. Replace ECU (engine) | |||||||||||

| if defective. | |||||||||||

| Fault code No. | Symptom | Power supply to the fuel pump relay is not normal. | |||||||||

| Used diagnostic code No. – – | |||||||||||

| Order | Inspection operation item and | Operation item and countermeasure | Reinstatement | ||||||||

| probable cause | method | ||||||||||

| Faulty battery | Replace or change the battery | Reinstated by | |||||||||

| Refer to “CHECKING AND CHARGING THE BAT- | starting the engine | ||||||||||

| TERY” in chapter 3. | and operating it at | ||||||||||

| idle. | |||||||||||

| Open or short circuit in wiring har- | Repair or replace if there is an open circuit. | ||||||||||

| ness. | • | Between battery and main switch | |||||||||

| red – red | |||||||||||

| • | Between main switch and fuse (ignition) | ||||||||||

| brown/blue – brown/blue | |||||||||||

| • | Between fuse (ignition) and ECU (engine) | ||||||||||

| red/white – red/white | |||||||||||

| Connected condition of connector | If there is a malfunction, repair it and connect it | ||||||||||

| Inspect the coupler for any pins | securely. | ||||||||||

| that may have pulled out. | ECU (engine) coupler | ||||||||||

| Check the locking condition of the | |||||||||||

| coupler. | |||||||||||

|

|

|

Воспользуйтесь поиском по сайту:

©2015 - 2026 megalektsii.ru Все авторские права принадлежат авторам лекционных материалов. Обратная связь с нами...