|

Digital circuit tester 90890-03174

|

|

|

|

Ш Measure the throttle position sensor volt-age.

Ш Adjust the throttle position sensor angle so that the voltage is within the specified range.

Throttle position sensor voltage 0.63 ~ 0.73 V

(yellow – black/blue)

Ъ After adjusting the throttle position sensor angle, tighten the throttle position sensor

screws 3.

▲▲▲▲▲▲▲▲▲▲▲ ▲▲▲▲▲▲▲▲▲ ▲▲▲▲▲▲▲▲▲▲▲▲

7 - 30

– +

ELEC 8

ELEC

ELEC

– +

– +

CHAPTER 8

ELECTRICAL SYSTEM

| ELECTRICAL COMPONENTS........................................................................ | 8-1 |

| CHECKING SWITCH CONTINUITY................................................................ | 8-4 |

| CHECKING THE SWITCHES.......................................................................... | 8-5 |

| CHECKING THE BULBS AND BULB SOCKETS.......................................... | 8-6 |

| TYPES OF BULBS.................................................................................... | 8-6 |

| CHECKING THE CONDITION OF THE BULBS....................................... | 8-7 |

| CHECKING THE CONDITION OF THE BULB SOCKETS....................... | 8-8 |

| IGNITION SYSTEM......................................................................................... | 8-9 |

| CIRCUIT DIAGRAM.................................................................................. | 8-9 |

| TROUBLESHOOTING............................................................................ | 8-10 |

| ELECTRIC STARTING SYSTEM.................................................................. | 8-15 |

| CIRCUIT DIAGRAM (XP500).................................................................. | 8-15 |

| CIRCUIT DIAGRAM (XP500A)................................................................ | 8-16 |

| STARTING CIRCUIT CUT-OFF SYSTEM OPERATION (XP500).......... | 8-17 |

| STARTING CIRCUIT CUT-OFF SYSTEM OPERATION (XP500A)....... | 8-18 |

| TROUBLESHOOTING............................................................................ | 8-19 |

| STARTER MOTOR........................................................................................ | 8-23 |

| CHECKING THE STARTER MOTOR..................................................... | 8-25 |

| ASSEMBLING THE STARTER MOTOR................................................. | 8-27 |

| CHARGING SYSTEM.................................................................................... | 8-28 |

| CIRCUIT DIAGRAM................................................................................ | 8-28 |

| TROUBLESHOOTING............................................................................ | 8-29 |

| LIGHTING SYSTEM...................................................................................... | 8-31 |

| CIRCUIT DIAGRAM................................................................................ | 8-31 |

| TROUBLESHOOTING............................................................................ | 8-33 |

| CHECKING THE LIGHTING SYSTEM.................................................... | 8-35 |

| SIGNALING SYSTEM................................................................................... | 8-39 |

| CIRCUIT DIAGRAM................................................................................ | 8-39 |

| TROUBLESHOOTING............................................................................ | 8-41 |

| CHECKING THE SIGNALING SYSTEM................................................. | 8-42 |

| COOLING SYSTEM....................................................................................... | 8-50 |

| CIRCUIT DIAGRAM................................................................................ | 8-50 |

| TROUBLESHOOTING............................................................................ | 8-51 |

| ELEC | ||||||||||

| –+ | ||||||||||

| IMMOBILIZER SYSTEM................................................................................ | 8-54 | |||||||||

| SYSTEM DIAGRAM................................................................................ | 8-54 | |||||||||

| CIRCUIT DIAGRAM................................................................................ | 8-55 | |||||||||

| GENERAL INFORMATION..................................................................... | 8-56 | |||||||||

| KEY CODE REGISTRATION.................................................................. | 8-57 | |||||||||

| SELF-DIAGNOSIS MALFUNCTION CODES.......................................... | 8-59 | |||||||||

| TROUBLESHOOTING............................................................................ | 8-61 | |||||||||

| CHECKING THE IMMOBILIZER SYSTEM............................................. | 8-62 | |||||||||

| PART REPLACEMENT KEY REGISTRATION REQUIREMENTS | 8-65......... |

ELECTRICAL COMPONENTS ELEC – +

ELECTRICAL COMPONENTS ELEC – +

|

|

|

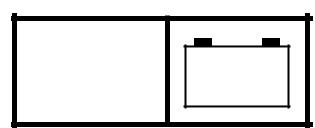

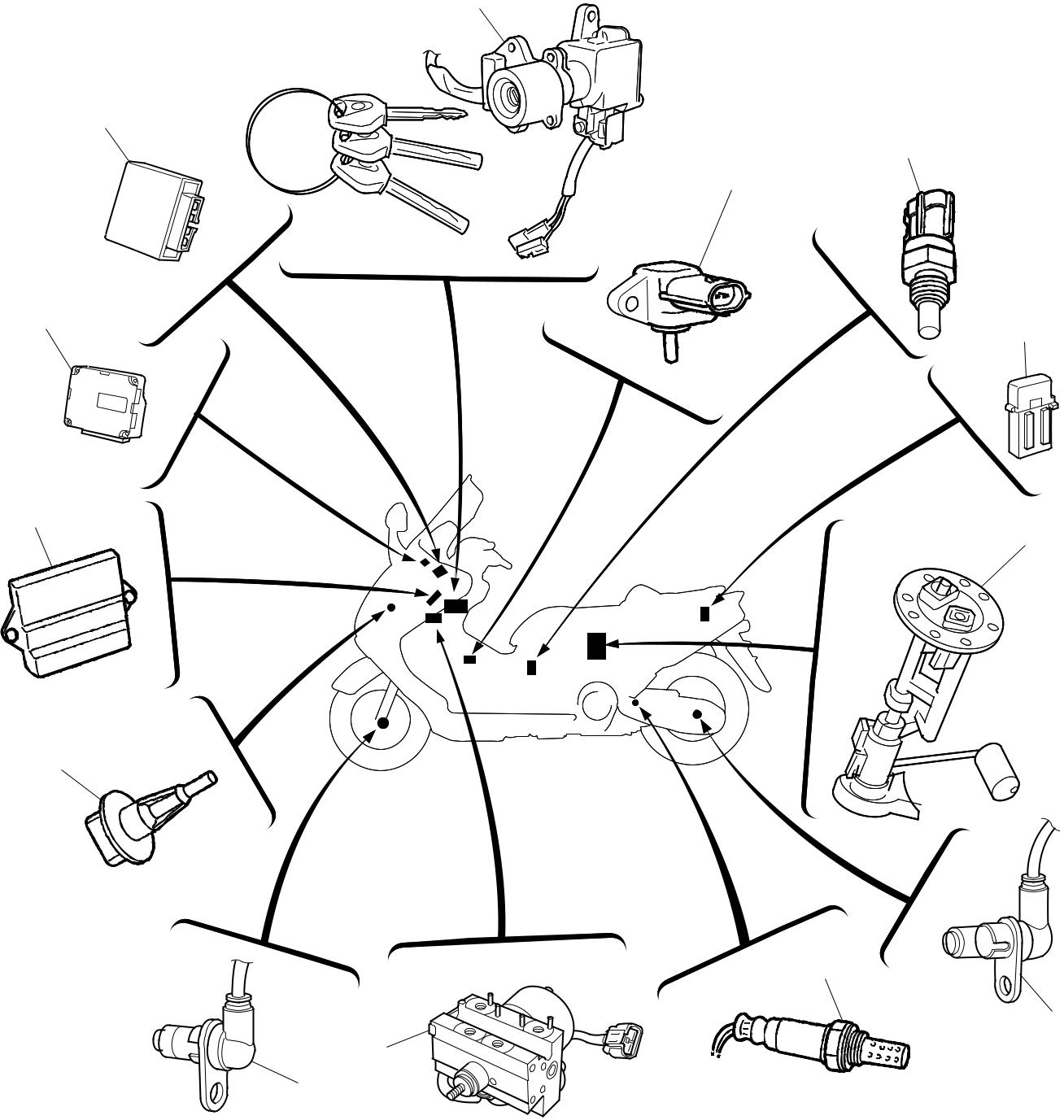

EAS00729

ELECTRICAL SYSTEM

ELECTRICAL COMPONENTS

1 Front brake light switch 8 Starter relay

2 Rear brake light switch 9 Main fuse

3 Turn signal/hazard relay 0 Rectifier/regulator

4 Starting circuit cut-off relay 1 A Sidestand switch

5 Starting circuit cut-off relay 2 (XP500A) B Crankshaft position sensor

|

|

|

6 Battery C Stator coil

7 Fuse box D Radiator fan

| L | ||

| K | ||

| J | ||

| I | ||

| H | ||

| G | ||

| F | ||

| E | ||

| D | A | |

| B | ||

| C | ||

| 8 - 1 |

ELECTRICAL COMPONENTS ELEC – +

ELECTRICAL COMPONENTS ELEC – +

E Speed sensor (XP500)

F Throttle position sensor

G Ignition coil

Ы Horn

Ы Lean angle cut-off switch

Ы Fuel injection system relay

Ы Headlight relay

Ы Radiator fan motor relay

| L | ||

| K | ||

| J | ||

| I | ||

| H | ||

| G | ||

| F | ||

| E | ||

| D | A | |

| B | ||

| C | ||

| 8 - 2 |

ELECTRICAL COMPONENTS ELEC – +

ELECTRICAL COMPONENTS ELEC – +

1 ECU (ABS) (XP500A)

21 Fail-safe relay (XP500A)

22 Main switch/immobilizer unit

23 Intake air pressure sensor

24 Coolant temperature sensor

25 ABS motor fuse

26 Fuel pump

27 Rear wheel sensor (XP500A)

28 O2 sensor

0 Hydraulic unit (XP500A)

A Front wheel sensor (XP500A)

B Intake air temperature sensor C ECU (engine)

| C | |

| B | |

| A | |

| 8 - 3 |

CHECKING SWITCH CONTINUITY ELEC – +

CHECKING SWITCH CONTINUITY ELEC – +

EAS00730

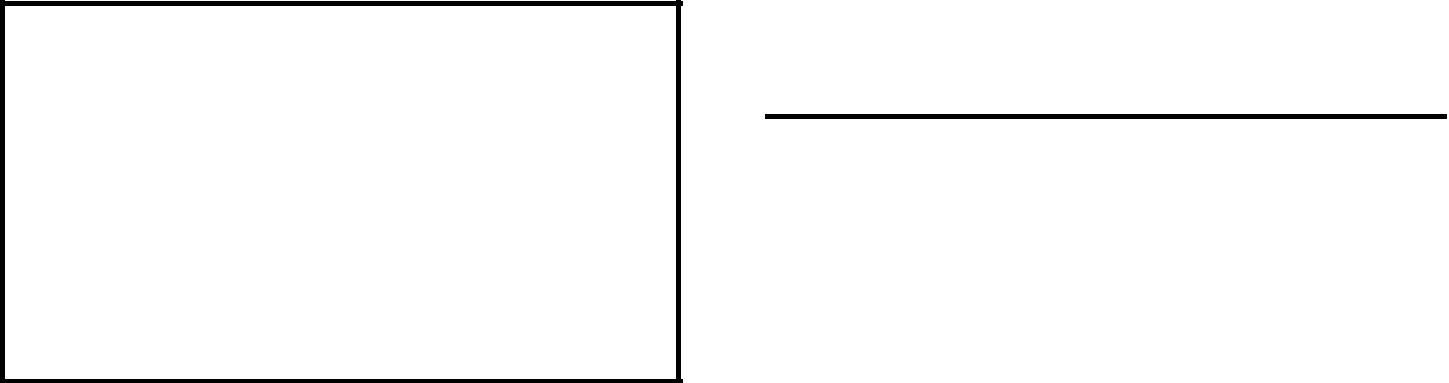

CHECKING SWITCH CONTINUITY

Check each switch for continuity with the pocket tester. If the continuity reading is incor-rect, check the wiring connections and if nec-essary, replace the switch.

CAUTION:

Never insert the tester probes into the cou-pler terminal slots 1. Always insert the probes from the opposite end of the cou-pler, taking care not to loosen or damage the leads.

Pocket tester 90890-03112, YU-03112-C

NOTE:

28 Before checking for continuity, set the pocket tester to “0” and to the “Ω Ч 1” range.

29 When checking for continuity, switch back and forth between the switch positions a few times.

The terminal connections for switches (e.g., main switch, engine stop switch) are shown in an illustration similar to the one on the left.

The switch positions a are shown in the far left column and the switch lead colors b are shown in the top row in the switch illustration.

NOTE:

“

” indicates a continuity of electricity between switch terminals (i.e., a closed circuit at the respective switch position).

” indicates a continuity of electricity between switch terminals (i.e., a closed circuit at the respective switch position).

The example illustration on the left shows that:

There is continuity between red, brown/blue, and brown/red when the switch is set to “ON”. There is continuity between red and brown/red when the switch is set to “  ”.

”.

8 - 4

CHECKING THE SWITCHES ELEC

CHECKING THE SWITCHES ELEC

– +

– +

EAS00731

CHECKING THE SWITCHES

Check each switch for damage or wear, proper connections, and also for continuity between the ter-minals. Refer to “CHECKING SWITCH CONTINUITY”.

Damage/wear → Repair or replace. Improperly connected → Properly connect.

Incorrect continuity reading → Replace the switch.

|

|

|

U 2

| R/Y Y | Y L/B G | |

–

PASS

Ch Br / W Dg

NR

N

| Br/R | R Br/L Br/R |

ON

OFF

R P

Br / L

A

L / W B

–

R / W R / B

R / W R / B

Ch Br / WDg L / Y Br / L

NL

4 5 B / Y L / Y

P B

–

| Br/W P B | Y G L/Y | |||||

| L/B R/Y | Dg Ch B/Y |

(BLUE)

B B

(BLUE)

R L / G

•

B

| Br G/Y | |||||||||||

| Dg | Br/W | Ch | G/Y | R/B | R/W | ||||||

| Br/L | L/Y | L/W | B | Br | |||||||

| (BLACK) | (BROWN) |

C

| 1 Pass switch | 6 Sidestand switch | A Hazard switch |

| 2 Dimmer switch | 7 Storage box light switch | B Front brake light switch |

| 3 Turn signal switch | 8 Main switch | C Fuse |

| 4 Horn switch | 9 Start switch | |

| 5 Rear brake light switch | 0 Engine stop switch |

8 - 5

CHECKING THE BULBS AND BULB SOCKETS ELEC – +

CHECKING THE BULBS AND BULB SOCKETS ELEC – +

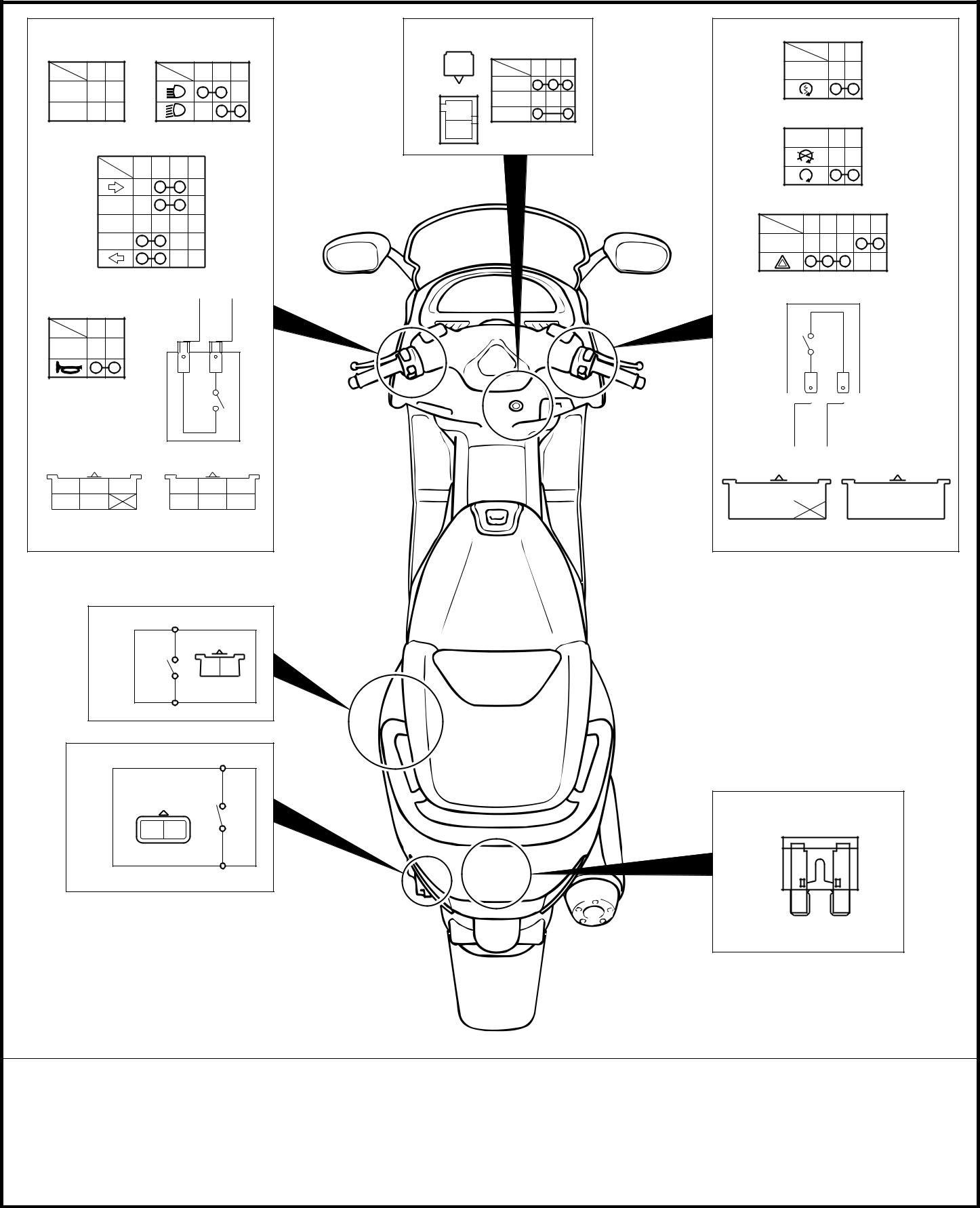

EAS00733

CHECKING THE BULBS AND

BULB SOCKETS

Check each bulb and bulb socket for damage or wear, proper connections, and also for con-tinuity between the terminals.

Damage/wear → Repair or replace the bulb, bulb socket or both.

Improperly connected → Properly connect. No continuity → Repair or replace the bulb, bulb socket or both.

TYPES OF BULBS

The bulbs used on this scooter are shown in the illustration on the left.

FF Bulbs A and B are used for the headlights and usually use a bulb holder that must be detached before removing the bulb. The majority of these types of bulbs can be removed from their respective socket by turning them counterclockwise.

GG Bulbs C is used for turn signal and tail/ brake lights and can be removed from the socket by pushing and turning the bulb counterclockwise.

HH Bulbs D and E are used for meter and indi-cator lights and can be removed from their respective socket by carefully pulling them out.

8 - 6

CHECKING THE BULBS AND BULB SOCKETS ELEC – +

CHECKING THE BULBS AND BULB SOCKETS ELEC – +

|

|

|